Bridging Design and Production: How DVT Drives Manufacturing Readiness

Moving a product from concept to full-scale production is a complex journey; one that requires more than successfully testing a prototype. After Engineering Validation Testing (EVT) confirms main functionality, Design Validation Testing (DVT) becomes the important next step. DVT makes sure the product design is mature, manufacturable, and ready for reliable pilot builds.

For OEM and ODM partners, DVT is where engineering intent meets manufacturing reality. At SVTronics, this phase serves as the essential bridge between early prototypes and scalable production.

From EVT to DVT: Maturing the Design for Real-World Builds

EVT prototypes validate engineering performance, but they are often hand-built, not optimized for repeatability. DVT pilot builds, on the other hand, are constructed using production-representative processes, materials, and tooling.

This transition is necessary because it allows teams to evaluate how the design behaves when produced in ways that emulate full manufacturing conditions. DVT checks the product can move from “it works” to “we can build it consistently.”

How DVT Bridges Design and Manufacturability

DVT connects design and manufacturing by building products like they will be made in production, checking that parts fit and assemble correctly, making sure needed components are available, testing for reliability, and finding issues early so they can be fixed before mass production.

1. Production-Representative Builds

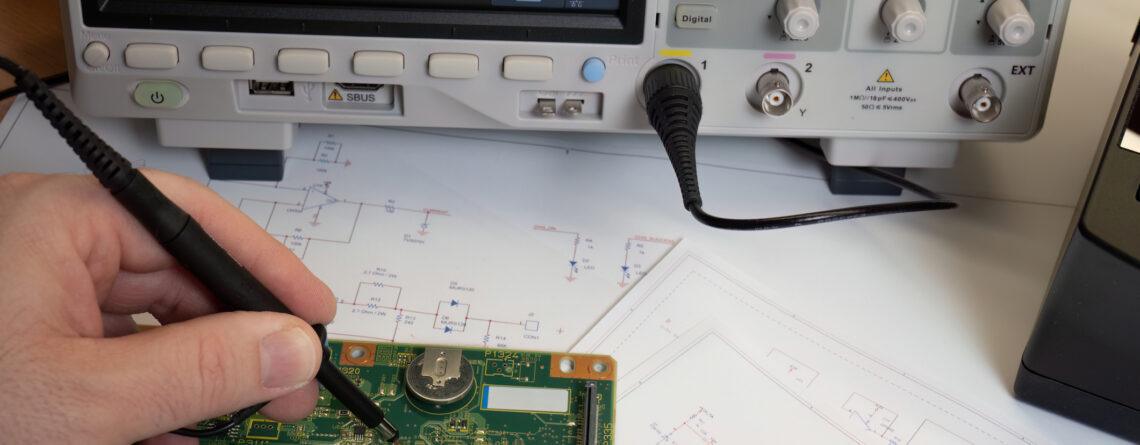

DVT units are assembled using processes that reflect actual manufacturing steps, such as automated SMT placement, standard assembly procedures, and realistic component sourcing.

This helps identify any misalignments between design intent and manufacturing practicality.

2. Validation of Tolerances and Assembly Processes

During DVT, engineers evaluate component tolerances, connector fits, thermal performance, and spacing to ensure the product can be built the same way every time.

This eliminates surprises that would otherwise appear during mass production.

3. Verification of Supply Chain Readiness

DVT confirms that the selected components are available, properly sourced, and stable.

It helps detect supply chain bottlenecks; long lead times, obsolete parts, or alternative component opportunities, before production ramps up.

4. Reinforced Quality and Reliability

Because DVT uses production-representative builds, reliability testing (thermal cycling, vibration, stress testing, etc.) provides insights that EVT prototypes cannot. This is where companies validate that the product can withstand real-world usage while being manufactured at scale.

5. Early Identification of Yield Issues

By evaluating build consistency, DVT exposes potential yield problems early. Issues like solder bridging, warpage, misalignment, or unexpected thermal drift can be corrected before they create delays during mass production.

How SVTronics Ensures Manufacturing Readiness Through DVT

At SVTronics, Design Validation Testing is fully integrated into our engineering and production workflows. We use DVT to refine the design, stabilize the supply chain, and prepare for the demands of Production Validation Testing (PVT).

Our DVT process includes:

Pilot manufacturing builds that mimic full-scale production

Cross-functional evaluation across engineering, quality, and manufacturing teams

DFM (Design for Manufacturability) and DFT (Design for Testability) refinements

Pre-compliance testing for EMI/EMC, thermal, and environmental standards

Comprehensive reliability and performance testing

Failure analysis and corrective action when issues arise

By the end of DVT, the design is robust, the supply chain is stable, and the production line is prepared for repeatable, high-quality output.

Building a Confident Path to Production

The gap between design and mass production is where many products encounter obstacles, from unexpected assembly issues to material shortages or overlooked reliability concerns. DVT closes this gap by transforming a validated design into a manufacturing-ready product.

For OEM and ODM companies, this means faster ramp-up, fewer redesigns, higher yield, and a smoother transition to market. At SVTronics, DVT isn’t just a testing phase, it’s a critical investment in scalable success.

Leave a Reply