Electronics Manufacturing

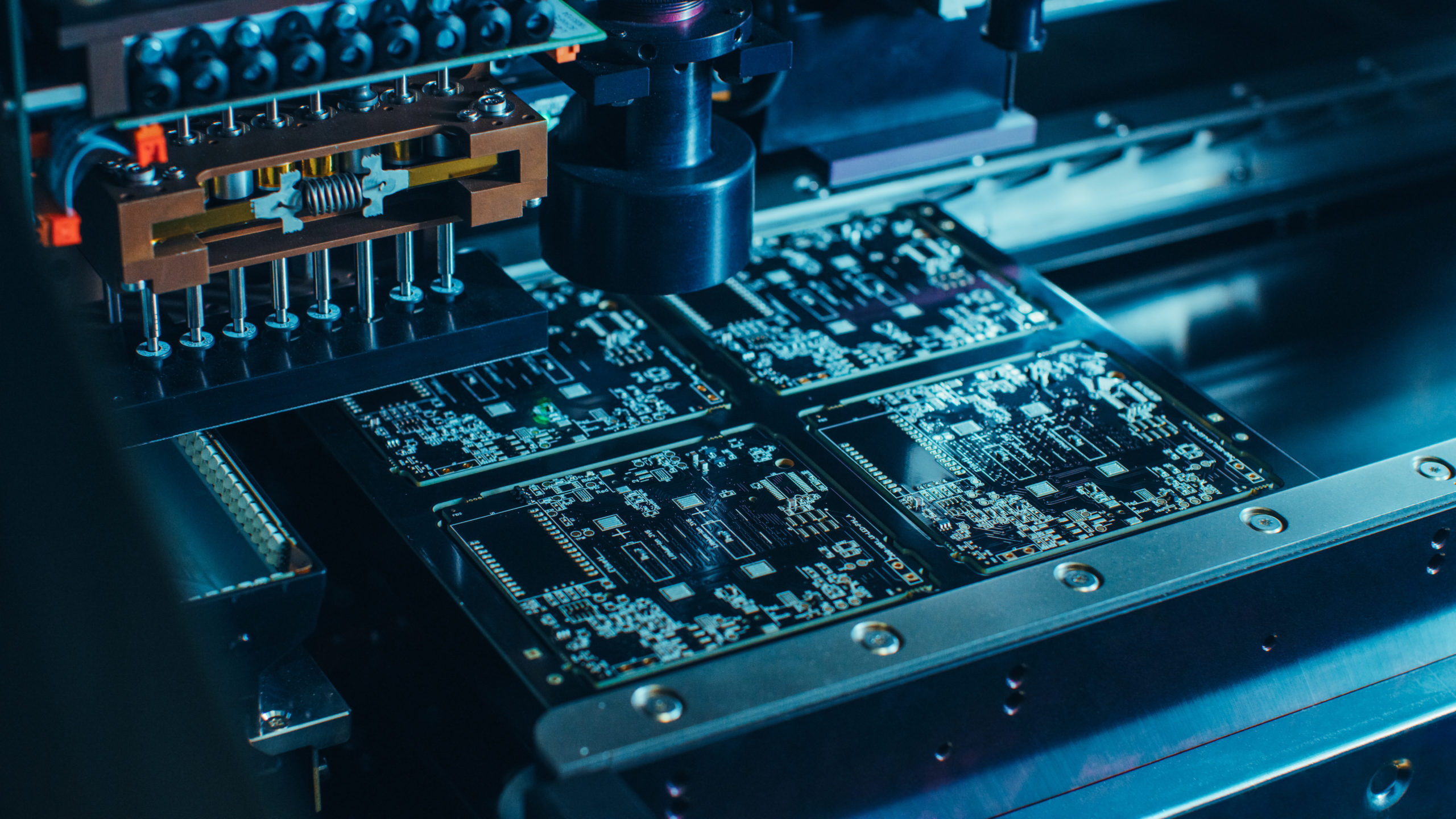

Advanced Electronics Assembly

SVTRONICS manufacturing facility is located in Plano, TX and is equipped with state-of-the-art machineries from leading equipment vendors and professional engineering team to deliver all your production needs from prototype thru production. With a qualified production process, innovative technology and highly skilled personnel we ensure complete customer satisfaction by delivering best quality products, on time, at the lowest cost.

- Six high speed SMT Assembly line consisting of Fuji & My Data Pick Place machines

- Machines capable of placing 01005 components, fine pitch and high count BGAs, Package on Package etc.

- Leaded/ Lead Free or Hybrid Process

- Nitrogen Purged reflow oven

- Automated Solder Paste printer

Electronics Manufacturing

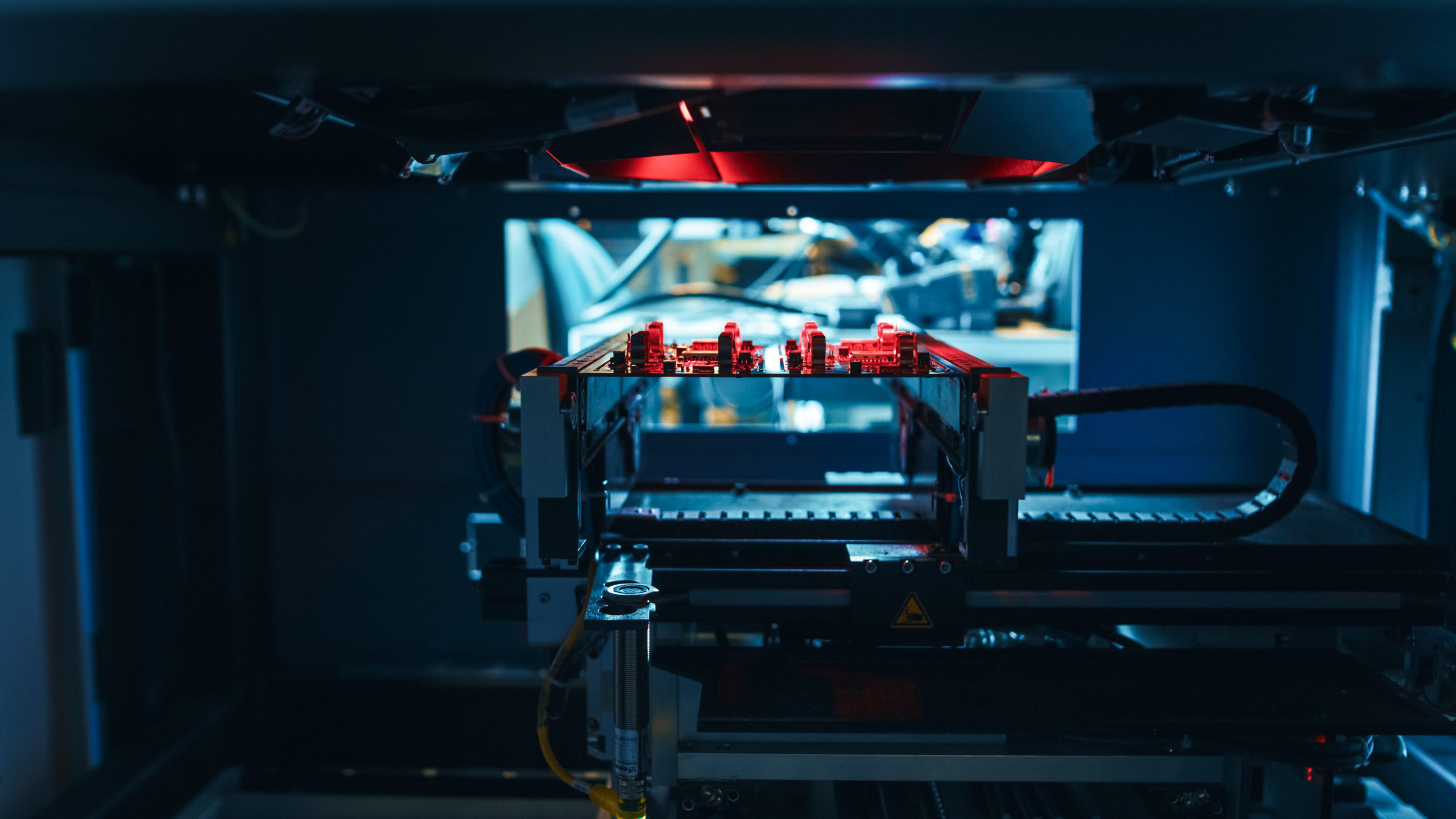

Electrical Testing

PC Boards assembled at SVT undergoes some level of testing to ensure quality and reliability. Depending on the nature of the boards being assembled and customer needs Svtronics has the following capabilities for performing electrical testing

- Flying probe testing using Seica Tester

- HP3070 In-circuit Testing

- Test fixture development

- Test Coverage Analysis

- Functional testing

- Boundary Scan

- Environmental and Stress Testing

Electronics Manufacturing

Inspection Capabilities

We use various State of the Art technology to ensure quality of PC boards manufactured at. These equipment’s enables us to 3D and 2D inspection of solder joints, component placement, placement accuracy etc.

- Automated Optical Inspection with 3D capabilities using and Mirtec MV 6 OMNIHP3070

- Nordson Dage X-ray station for BGA and fine pitch soldering inspection

- SJ Innotech 3D Solder Paste inspection to measure solder paste volume

Engineering Services

CAD/ CAM DFM

Svtronics offers an extensive range of value-add engineering services that complement our complete end-to-end manufacturing strategy to provide the customers the best values

- Engineering for Manufacturing review to ensure manufacturability

- NPI Engineering to ensure a smooth product launch

- BOM scrubbing to ensure part availability and pricing

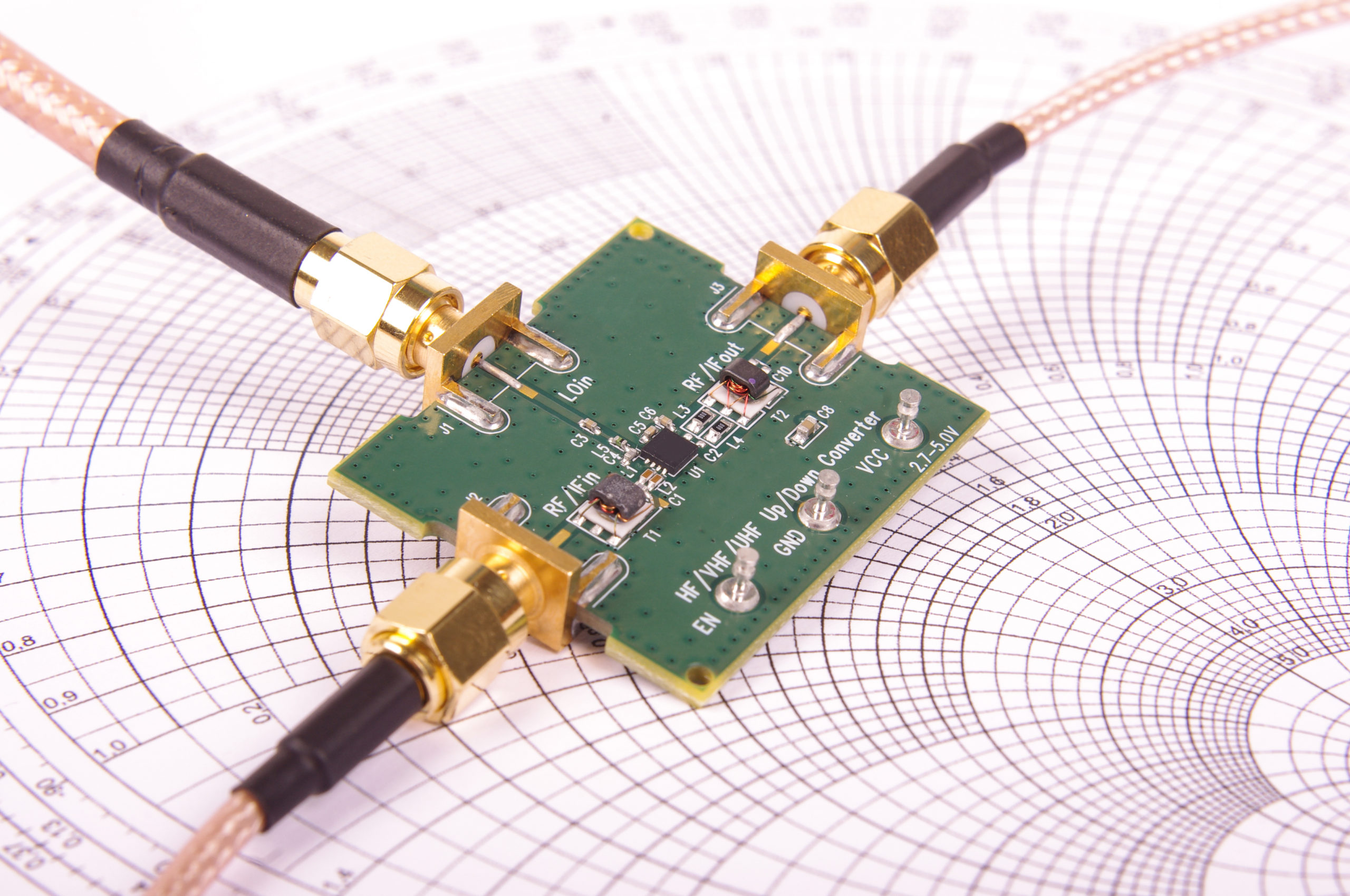

Engineering Services

Compliance Testing

We work with 3rd party vendors to provide a complete range of compliance testing services

- EMI/ EMC Compliance testing

- FCC/ UL Certification

Engineering Services

PCB Layout and Schematics

Svtronics Engineering team can work independently or work as an extension of your existing team to provide a variety of engineering service

- compiling product specifications

- Component evaluation and specification

- Schematics capture and PCB Layout

- BOM optimization for cost reduction

- PCB Engineering and Layer optimization – for cost and electrical engineering performance

- Prototyping

- Support during certification

Mechanical Engineering

Prototype Modeling & Rendering

Svtronics mechanical engineering team works closely with our customers provide superior industrial engineering concepts and end-product results.

- Prototype development and renderings

- Material and manufacturing specifications

- Injection molded plastics

- Chassis, enclosure, and panel engineering

- Prototyping of mechanical parts using including 3D printing services

- Manufacturing support

Expert Manufacturing For Your Industry

- ISO 9001:2015 and AS9100D

- ISO 13485

- ITAR Registered

- HUB Certificate

- SBE Certificate

- IPC 610

- IPC 620

- SMTA

- Minority Business Certification

Certified to serve a diverse variety of demanding, and cutting-edge market segments

Core Competencies

- New Production Introduction (NPI)

- High Mix Low Volume Production

- Mass Production ( High volume Low Mix)

- Placement capability for 01005 package components

- Package On Package (PoP)

- Flying Probe and In Circuit testing

- Thru Hole Technology – Selective Soldering/Wave Soldering

- Box Build and System assembly

- Coating/Potting

- Final Packaging and Out of the Box experience

Quality Management System

QC Practices

- Incoming Material inspection

- In line production Quality control

- Integrated First Article inspection tool

- Document control – strict ECO process

- Manual and Automated inspection

- X-ray inspection

- In-line solder paste inspection

- Flying probe and In-Circuit testing

- Electro-Static Discharge (ESD) Control

Finished Good Quality control

Let’s build something incredible

Upload the details to have our system price your next project