What Materials Are Used in PCB Manufacturing—and Why They Matter

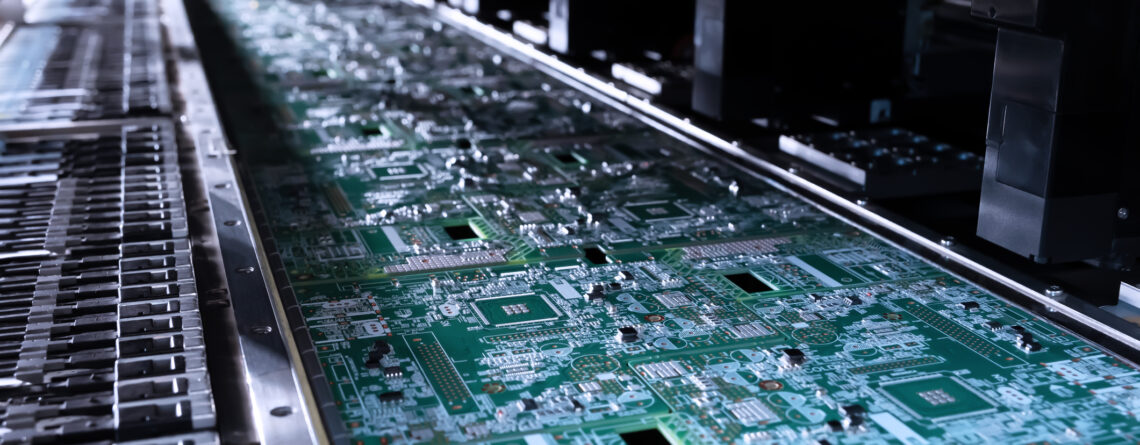

When it comes to printed circuit board (PCB) manufacturing, the materials used play a critical role in performance, durability, and reliability. As a leading PCB assembly manufacturer, SVTronics emphasizes the importance of choosing high-quality materials to ensure optimal results during printed circuit board assembly and throughout a product’s lifecycle.

In this blog, we’ll explore the key materials involved in PCB manufacturing—laminate, prepreg, and copper foil—and explain why each is vital for board stability, insulation, and conductivity.

Laminate: The Foundation of Every PCB

Laminate serves as the base layer of the PCB, providing mechanical strength and insulation. Typically made from woven glass reinforced with resin, laminate ensures that the PCB can support components and withstand the mechanical and thermal stresses encountered during assembly and real-world operation.

In most cases, epoxy glass laminates are used due to their excellent dielectric properties and stability, making them a top choice for high-performance electronics.

Prepreg: The Binding Layer

Prepreg, short for pre-impregnated composite fibers, is a sheet of woven glass reinforcement infused with resin that is partially cured. This material acts as a bonding agent between layers of laminate in multilayer PCBs. When heated and pressed, the resin in the prepreg melts and hardens, binding the layers together to create a strong and uniform structure.

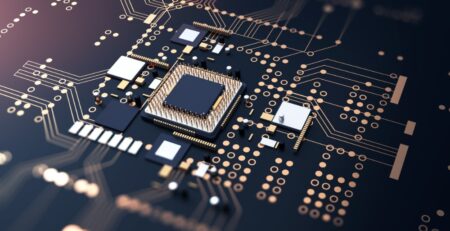

Copper Foil: The Conductor

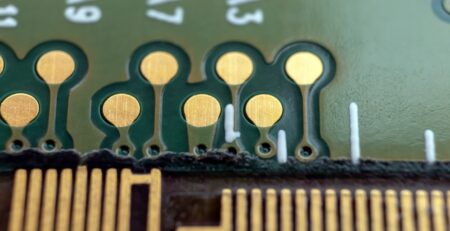

Copper foil is the conductive material that forms the electrical pathways of the PCB. During manufacturing, copper layers are etched to create the circuit patterns that connect various electronic components. Copper is preferred because of its excellent electrical conductivity and ability to maintain signal integrity even at high speeds.

The thickness of the copper foil can vary depending on the current requirements and the application, with thicker copper being used in high-power or industrial applications.

Why Material Selection Matters

Selecting the right materials is crucial for ensuring the long-term reliability and performance of a PCB. Each layer—laminate, prepreg, and copper foil—contributes to the mechanical stability, thermal efficiency, and electrical performance of the board.

As a trusted PCB assembly manufacturer, SVTronics partners with clients to ensure every board meets their specific design requirements and industry standards.

Partner with SVTronics for Expert PCB Manufacturing

The success of any electronic device starts with the materials used in its PCB. By working with PCB assembly manufacturer SVTronics, you gain a partner who understands the importance of material selection and provides end-to-end printed circuit board assembly services designed for precision, reliability, and performance.

Contact us today to learn how we can help with your next project, from material selection to complete PCB assembly.

Leave a Reply