Understanding High-Density Interconnect (HDI) PCBs

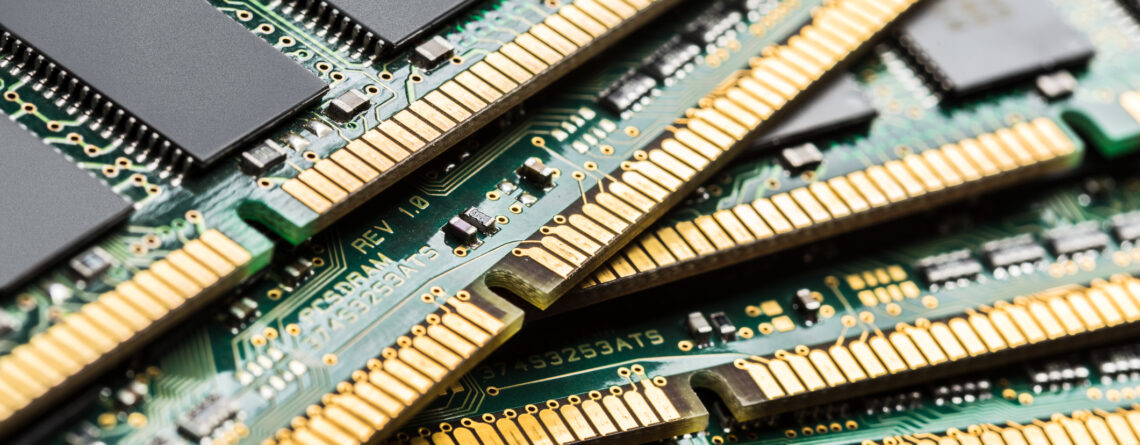

As electronics become smaller, faster, and more powerful, printed circuit boards (PCBs) must evolve to keep pace. Traditional PCB designs often struggle to deliver the density and performance modern devices require. This is where High-Density Interconnect (HDI) PCBs come in.

HDI PCBs enable manufacturers to incorporate more functions into smaller spaces without losing reliability. From smartphones to medical devices, they play a crucial role in today’s cutting-edge technology.

What Sets HDI PCBs Apart?

Unlike standard PCBs, HDI boards use advanced interconnect technologies to handle higher complexity in smaller areas. Their defining features include:

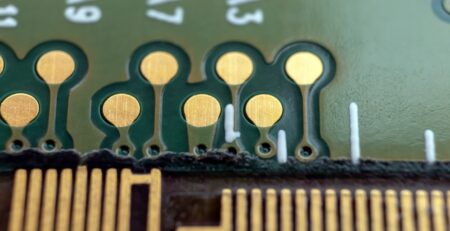

- Microvias: Smaller than traditional vias, microvias improve routing efficiency and free up valuable space.

- Blind and Buried Vias: These vias connect only specific layers, reducing congestion and enhancing performance.

- Fine Space and Trace: HDI PCBs allow for much smaller trace widths, enabling more connections in limited real estate.

- Thin Dielectrics: Slim insulation layers between copper layers keep the board compact while maintaining signal integrity.

Together, these design features enable HDI PCBs to reach higher circuit densities and offer greater functionality than standard designs.

Why HDI Matters in Modern Electronics

The demand for compact, high-performance electronics is only growing. HDI PCBs make this possible by:

- Enabling Miniaturization: Essential for smartphones, wearables, and medical implants where space is limited.

- Boosting Performance: Shorter signal paths reduce delay and improve signal integrity for faster, more reliable devices.

- Supporting Complex Designs: As chips integrate more functionality, HDI boards provide the routing flexibility needed.

- Reducing Layer Counts: Using efficient interconnects, HDI designs often achieve more with fewer layers, lowering costs and weight.

Applications of HDI PCBs

HDI technology is common in industries where both performance and size matter:

- Consumer Electronics: Smartphones, tablets, and laptops rely on HDI PCBs for their sleek designs and high power.

- Medical Devices: Pacemakers, imaging equipment, and handheld diagnostic tools benefit from compact, reliable boards.

- Automotive Systems: HDI is used for high performance in advanced driver assistance systems (ADAS), sensors, and infotainment systems.

- Aerospace & Defense: HDI boards ensure reliability under extreme conditions while minimizing size and weight.

SVTronics’ Expertise in HDI PCB Manufacturing

At SVTronics, HDI PCB manufacturing is backed by decades of engineering experience and advanced production capabilities. Our team provides:

- Engineering Support: Helping clients optimize layouts for density and performance.

- Precision Manufacturing: Utilizing microvia drilling, sequential lamination, and advanced soldering techniques.

- Comprehensive Testing: Ensuring reliability through X-ray inspection, in-circuit testing, and stress simulations.

- Industry Certifications: Compliance with ITAR, ISO, AS9100D, and IPC standards for quality and reliability.

Unlock the Future of Electronics with SVTronics’ Advanced HDI PCBs

In today’s fast-paced world of compact, high-performance electronics, HDI PCBs are more than just an upgrade—they’re essential. Featuring advanced elements like microvias, blind and buried vias, and sub 3 mil Trace and Space routing, HDI PCBs provide unmatched functionality in a smaller size, making them the foundation of next-generation technology.

At SVTronics, we focus on turning your most ambitious ideas into reality. Whether you’re creating innovative consumer gadgets or mission-critical aerospace systems, our expertise and cutting-edge technology ensure your HDI PCBs meet the highest standards of performance, reliability, and scalability.

Why settle for ordinary when you can achieve something extraordinary? Partner with SVTronics and feel the difference in precision, quality, and innovation. Let’s build the future together—contact us today to get started!

Leave a Reply