Rigid vs. Flexible PCBs: Which Is Right for Your Product?

Printed circuit boards (PCBs) come in many forms, but two of the most widely used types are rigid and flexible PCBs. Choosing the right PCB type for your application can impact everything from performance and durability to cost and manufacturability.

At SVTronics, we assist clients in navigating their choices by understanding the strengths and trade-offs of each option. Here’s a closer look at rigid versus flexible PCBs and guidance on determining which is best suited for your product.

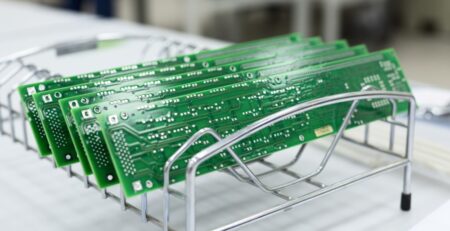

What Is a Rigid PCB?

A rigid PCB is made from solid, non-flexible materials like fiberglass-reinforced epoxy laminate. These boards retain their shape throughout their lifespan and are ideal for applications where the circuit board will remain stationary and protected within a device enclosure.

Advantages of Rigid PCBs:

- Cost-effective for high-volume manufacturing

- Strong mechanical stability

- Easier to manufacture and handle during assembly

- High component density supported

Common Applications:

- Consumer electronics (e.g., televisions, desktops)

- Industrial control systems

- Medical imaging devices

- Automotive systems

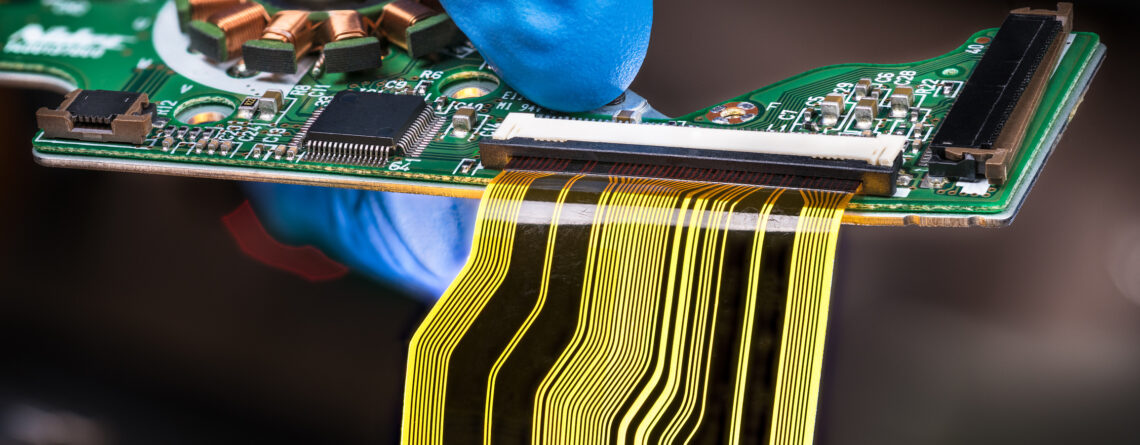

What Is a Flexible PCB?

A flexible PCB is made from materials like polyimide or other high-temperature plastics that allow the board to bend or fold. These boards are lightweight, adaptable, and often used where space constraints or motion are involved.

Advantages of Flexible PCBs:

- Can bend and fold to fit compact or irregular spaces

- Reduced weight and improved space efficiency

- Greater resistance to vibration and mechanical stress

- Ideal for dynamic applications where the board moves or flexes

Common Applications:

- Wearable technology

- Aerospace and defense systems

- Medical implants and diagnostic tools

- Mobile phones and compact electronics

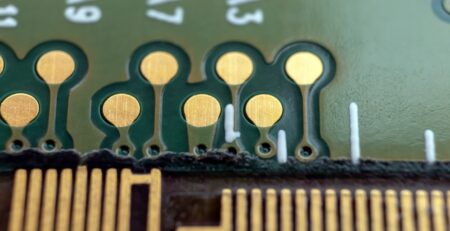

What About Rigid-Flex PCBs?

Rigid-flex PCBs combine elements of both rigid and flexible boards. These hybrid PCBs are often used in applications that require a compact, lightweight solution with complex interconnections and limited space.

While more complex and expensive to manufacture, rigid-flex designs can reduce part counts, eliminate connectors, and enhance reliability, especially in high-performance or mission-critical environments.

How to Choose the Right PCB for Your Product

Selecting between rigid and flexible PCBs depends on your product’s mechanical, electrical, and environmental requirements. Consider the following when making your choice:

- Will the board remain static or move during operation?

- How much space is available for board placement?

- What are your durability and vibration resistance needs?

- Is weight reduction a critical factor?

- What is your project’s budget and production volume?

Need Help Deciding? SVTronics Can Help.

Choosing the correct type of PCB is important for your product to work well. At SVTronics, we offer our engineering expertise and manufacturing flexibility to help you design and build the optimal PCB—whether rigid, flexible, or a combination of both.

Contact us today to discuss your application and explore the best solution for your needs.

Leave a Reply