Production Validation Testing: The Final Check Before Mass Manufacturing

Reaching the final stages of product development is a major milestone, but it doesn’t mean the product is ready for mass manufacturing just yet. After EVT validates core functionality and DVT proves system-level performance and manufacturability, there is one step left: Production Validation Testing (PVT).

PVT is where the production line, processes, and quality controls are tested under real manufacturing conditions. It’s the final checkpoint that determines whether a product is truly ready for high-volume manufacturing.

At SVTronics, PVT ensures the production environment is stable, repeatable, and capable of delivering consistent quality at scale.

What Is Production Validation Testing (PVT)?

Production Validation Testing focuses on verifying that the manufacturing process, not just the product design, is ready for mass production. While EVT and DVT evaluate functionality and design integrity, PVT evaluates:

- Production line performance

- Yield predictability

- Operator instructions and workflow readiness

- Test station reliability

- Throughput and takt time

- Consistent build quality at volume

PVT is the closest simulation of mass production before committing to full manufacturing scale.

Key Goals of PVT

Learn about the main goals of PVT include line qualification, throughput and capacity testing, quality and yield validation.

1. Line Qualification

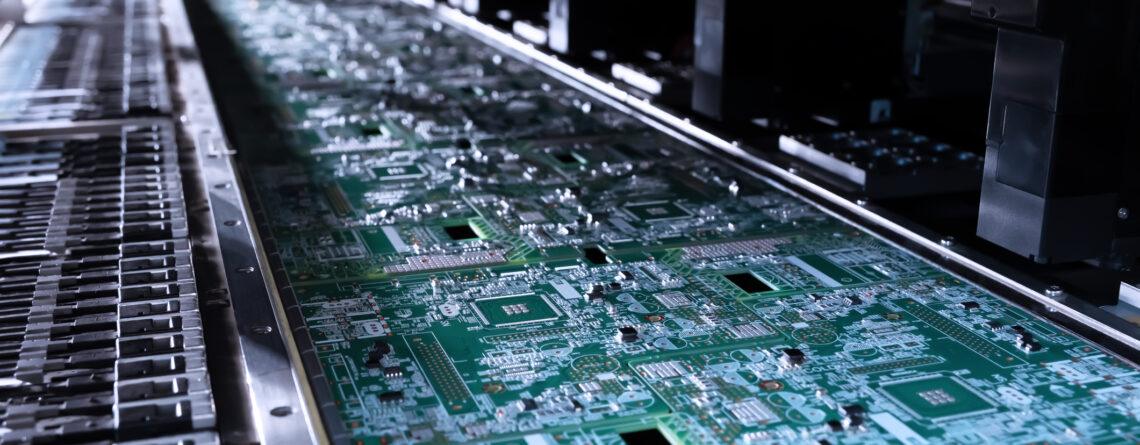

PVT qualifies the production line by confirming that equipment, tooling, fixtures, and test stations work seamlessly together.

This includes validating:

- SMT placement accuracy

- Assembly workflows

- Automated and manual inspection processes

- End-of-line test systems

Line qualification ensures that the production floor is prepared to handle volume without interruptions or quality drift.

2. Throughput and Capacity Testing

PVT measures how efficiently the line can run at expected production rates.

This includes evaluating:

- Cycle times

- Takt time requirements

- Production bottlenecks

- Operator load balancing

Throughput testing confirms the line can meet forecasted demand and allows for adjustments before scaling up.

3. Quality and Yield Validation

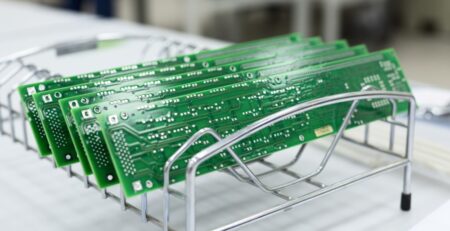

During PVT, units are built using full production processes so yield data reflects real conditions.

This phase identifies:

- Assembly defects

- Thermal or electrical inconsistencies

- Component placement issues

- Firmware loading or calibration failures

The goal is to achieve stable, predictable yield numbers, setting the benchmark for mass production.

Why PVT Is Essential for Production Success

Skipping or minimizing PVT can lead to costly consequences once mass manufacturing begins, such as:

- Unanticipated downtime

- Low yields

- Excessive rework

- Delayed shipments

- Increased cost per unit

- Missed launch windows

PVT eliminates these risks by ensuring that both the product and the production process perform reliably at scale.

SVTronics’ Approach to PVT: Full Validation Before Volume

At SVTronics, Production Validation Testing is a disciplined, data-driven process. Our goal is simple: ensure a flawless transition from pilot builds to full-scale manufacturing.

Our PVT process includes:

- Production-representative builds using final tooling, materials, and assembly methods

- Validation of all work instructions and test procedures

- Yield tracking and statistical process control (SPC)

- Test station accuracy and repeatability checks

- Operator training and skill verification

- Final DFM/DFT refinements to maximize efficiency and consistency

By the end of PVT, your production line is not just qualified; it’s optimized for stable, high-quality output.

The Final Gate Before Successful Mass Manufacturing

Production Validation Testing is more than a formality, it’s the last safeguard ensuring that production can scale predictably, efficiently, and without surprises.

Once a product passes PVT, OEM and ODM teams can move into mass manufacturing with confidence, knowing the process is robust and repeatable.

At SVTronics, we help bring products to market with precision, speed, and reliability; every step of the way, from EVT to DVT to PVT.

Leave a Reply