How PCB Prototyping Accelerates Product Launches

In the electronics industry, speed to market is everything. Companies moving quickly from concept to production gain a significant competitive advantage. However, rushing without proper validation often leads to costly mistakes and delays.

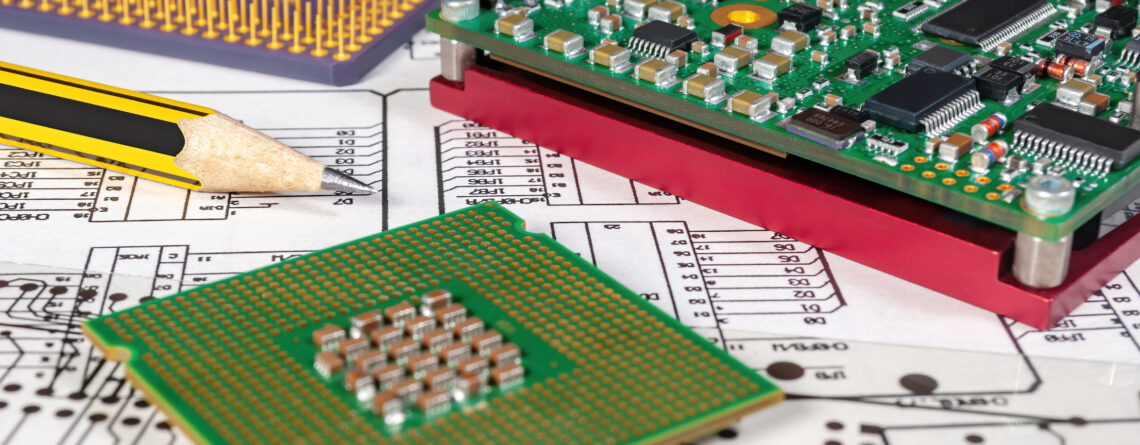

This is where PCB prototyping comes in. PCB prototyping helps ensure products launch faster and with greater reliability by testing designs early, identifying flaws, and fine-tuning performance.

The Role of Prototyping in Product Development

PCB prototyping is more than just building an early version of a circuit board. It’s an essential step in the development process that allows engineers to:

- Validate Design Concepts: Ensure the board functions as intended before scaling to production.

- Identify Flaws Early: Catching errors at the prototype stage saves time and prevents expensive redesigns later.

- Optimize for Performance: Test signal integrity, thermal behavior, and mechanical durability.

- Reduce Risk: Minimize the chance of defects or failures in final production runs.

Benefits of Early Testing

Moving quickly into prototyping offers clear advantages for electronics manufacturers:

- Shorter Time to Market: By resolving issues early, companies can avoid production setbacks and meet launch deadlines.

- Improved Quality: Prototypes allow multiple testing iterations, ensuring the final product meets specifications.

- Cost Savings: Fixing errors before production prevents wasted materials and reduces rework.

- Better Collaboration: Engineers, designers, and manufacturers can align more effectively when they can see and test a physical board.

Fine-Tuning Before Mass Production

Prototyping also allows teams to refine designs before committing to large-scale manufacturing. This includes:

- Component Placement Adjustments: Optimizing layout for performance and assembly efficiency.

- Thermal Management Improvements: Addressing heat dissipation to extend product life.

- Manufacturability Reviews: Ensuring the design is ready for high-volume production.

By addressing these details early, companies reduce the risk of recalls, warranty claims, and performance issues in the field.

SVTronics’ PCB Prototyping Advantage

At SVTronics, we understand that prototyping is essential to a product’s success. When you work with us, you can innovate quickly while ensuring your products are built on a foundation of reliability and quality. Our capabilities include:

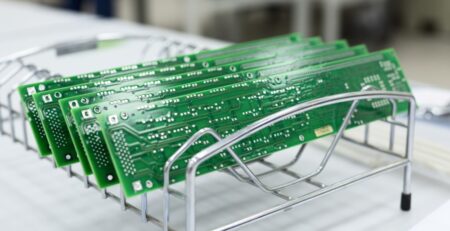

- Rapid Prototyping Services: Fast turnaround times to keep development cycles moving.

- Engineering Support: Collaborative design reviews and optimization for manufacturability.

- Advanced Testing: In-circuit, flying probe, and environmental testing to validate reliability.

- Seamless Transition to Production: Scalable solutions that move smoothly from prototype to high-volume manufacturing.

Accelerating Product Launches with PCB Prototyping

PCB prototyping is more than a step in the process; it bridges the concept to the market-ready product. Prototyping accelerates product launches and reduces risks by validating designs early, identifying flaws, and refining performance.

For companies looking to stay ahead of the competition, SVTronics provides the tools, expertise, and speed needed to bring innovative products to life faster than ever.

Leave a Reply