Engineering Validation Testing: The Critical First Step in Product Reliability

Engineering Validation Testing (EVT) is a crucial early step that confirms your product design works as intended, helping you avoid future problems and expenses. Understanding EVT’s purpose and common outcomes enables smarter choices for smoother development and better results.

Building Confidence in Product Design

Before a product ever reaches mass production, it must first prove that its design is sound, functional, and reliable. This confirmation happens during Engineering Validation Testing (EVT), the first major checkpoint in a product’s journey from prototype to production. EVT ensures that every component and subsystem operates as intended, laying the foundation for product reliability and long-term success.

At this stage, the focus isn’t on cosmetics or scalability. Instead, EVT is about answering one fundamental question: “Does this design actually work?”

What Is Engineering Validation Testing (EVT)?

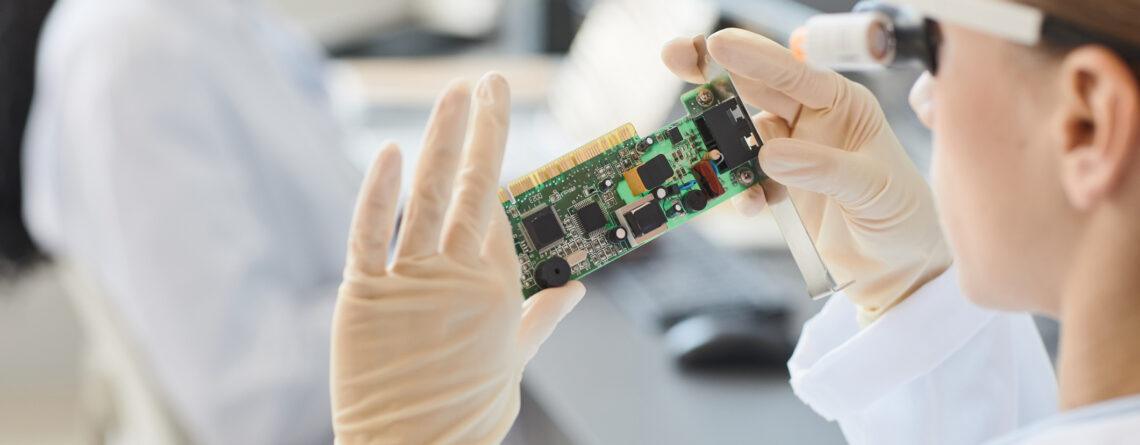

Engineering Validation Testing is the initial phase of hardware validation where prototypes are rigorously tested to verify the core functionality and design integrity of a product.

This is typically the first build that closely resembles the intended final product, using production-like components whenever possible. EVT bridges the gap between concept and reality, providing critical insights before any large investments are made in tooling, mass production, or supply chain logistics.

During EVT, engineers focus on:

- Evaluating electrical, mechanical, and thermal performance across all major components and subsystems

- Verifying functional specifications, ensuring the product performs its intended tasks under expected conditions

- Identifying design flaws and tolerance issues early, before they cascade into larger failures

- Conducting stress and environmental testing to assess reliability and durability

Why EVT Matters: Catching Problems Before They Multiply

Skipping or underestimating EVT can lead to expensive setbacks later in the development process. The earlier a defect is found, the easier, and cheaper, it is to fix. EVT serves as the “safety net” that protects against downstream delays and costly redesigns.

Some of the key benefits include:

- Early issue detection: Identifies electrical or mechanical weaknesses before they become production blockers.

- Improved product reliability: Ensures the design can withstand real-world use and environmental stress.

- Faster development cycles: Reduces time spent debugging and redesigning during later phases (DVT and PVT).

- Lower production costs: Minimizes rework, tooling changes, and material waste once the design is finalized.

In short, EVT is where problems are welcomed because finding them now means avoiding them later.

Typical Deliverables in EVT

A successful EVT phase produces more than just test data. It results in tangible documentation and design refinements that move the product closer to market readiness. Common deliverables include:

- EVT prototype units for testing and evaluation

- Detailed test reports, including pass/fail results and root-cause analyses

- Updated schematics, PCB layouts, and firmware baselines

- Defect logs with recommended corrective actions

By the end of EVT, the goal is clear: no blocking design issues remain, and all critical functions are validated. This creates a stable foundation for the next phase, Design Validation Testing (DVT), where integration and manufacturability take center stage.

How EVT Reduces Downstream Costs and Delays

Think of EVT as an insurance policy for your product development process. Every failure uncovered at this stage prevents a far more expensive issue from surfacing later in the production line.

For example:

- A thermal design flaw caught during EVT might cost a few hundred dollars to fix. If found during production, it could result in thousands of dollars in scrapped materials and missed launch deadlines.

- An electrical short identified in EVT might lead to a quick board revision. If discovered after tooling is complete, it could require an entirely new production batch.

By validating functionality, reliability, and performance early, EVT ensures that time and resources are invested only into a proven design, reducing risk and accelerating the path to market.

A Strong Start for a Reliable Product

Engineering Validation Testing isn’t just another box to check; it’s the first step toward product reliability and market success. By catching design issues early, verifying performance, and confirming that each component works as intended, EVT gives engineering teams the confidence to move forward. A product that passes EVT isn’t perfect yet, but it’s proven capable, and that’s what makes it ready for refinement, optimization, and eventual production.

SVTronics’ expert test engineers perform thorough evaluations, guaranteeing the highest functionality and reliability for every product. Reach out today and discover how our Engineering Validation Testing can give you confidence and peace of mind in your products’ performance.

Leave a Reply