Design Validation Testing: Where Product Design Meets Real-World Performance

Bringing a product from concept to market is more than just perfecting a schematic, it’s about proving that the design can perform reliably in the real world. That’s where Design Validation Testing (DVT) plays a pivotal role. At SVTronics, we view DVT as the bridge between engineering innovation and market readiness, making sure what works in theory also works in production.

What Is Design Validation Testing (DVT)?

Design Validation Testing is the phase where a product design is validated against the full set of functional, environmental, and regulatory requirements. Unlike Engineering Validation Testing (EVT), which verifies that the design functions as intended, DVT confirms that all systems, such as electrical, mechanical, and software, work together under realistic conditions.

The goal is simple: to ensure the product is reliable, manufacturable, and compliant before mass production begins.

Why DVT Matters: From Functionality to Market-Readiness

Skipping or compressing the DVT phase can lead to critical issues that compromise product quality or delay launch. DVT identifies potential weaknesses early enough to fix them without derailing production schedules or budgets.

Here’s what a comprehensive DVT program accomplishes:

-

Ensures System-Level Reliability

- DVT validates that each subsystem, like hardware, firmware, and mechanical components, functions cohesively under normal and extreme conditions. Stress testing and environmental simulations reveal vulnerabilities that may not appear during basic prototype testing.

-

Confirms Manufacturability

- Design Validation Testing helps verify that products can be consistently produced at scale. It identifies issues related to component tolerances, assembly processes, and thermal performance that could impact yield or quality once production ramps up.

-

Verifies Regulatory Compliance (EMI/EMC and Beyond)

- In today’s regulatory landscape, compliance isn’t optional. DVT ensures adherence to electromagnetic interference (EMI) and electromagnetic compatibility (EMC) standards, as well as other applicable safety and environmental regulations. This step reduces the risk of costly certification failures later in the process.

-

Reduces Risk in Final Tooling and Production

- By confirming both design integrity and manufacturability, DVT minimizes the chance of expensive rework after tooling and production setup. It essentially “de-risks” the path to full-scale manufacturing.

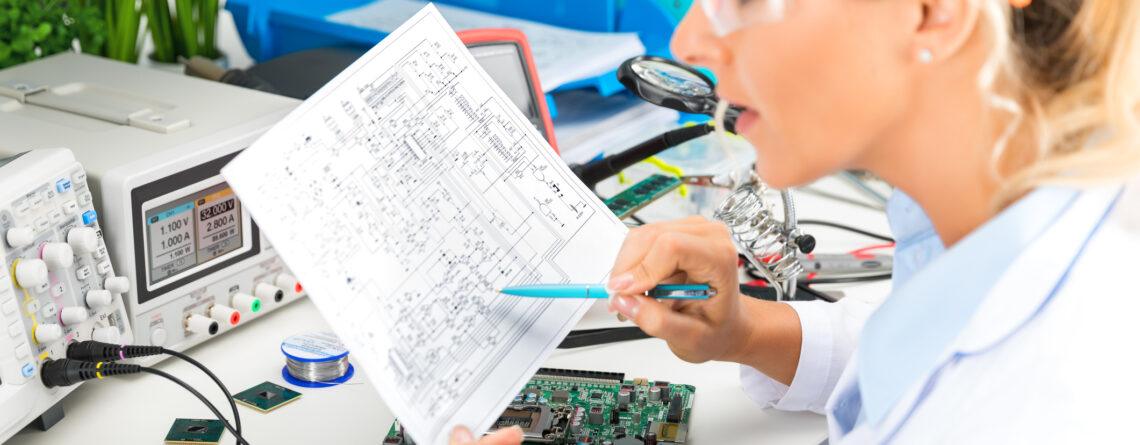

The DVT Process: SVTronics’ Proven Approach

At SVTronics, DVT is an integrated part of our end-to-end manufacturing and engineering solutions. Our testing process is designed to confirm that every aspect of a product meets its design intent, performance expectations, and compliance requirements.

We conduct thorough evaluations across:

- Electrical testing: Verifying power, signal integrity, and interface functionality.

- Mechanical validation: Ensuring durability, fit, and environmental resilience.

- Firmware and software integration: Testing communication between embedded systems and application layers.

- Regulatory testing: Pre-compliance evaluation for EMI/EMC, thermal, and environmental standards.

Our cross-disciplinary teams spanning engineering, manufacturing, and quality, collaborate closely during DVT to capture real-world insights and prepare the design for seamless transition into Production Validation Testing (PVT).

Beyond Validation: Building Confidence in Every Product

Design Validation Testing doesn’t just verify performance, it builds confidence. It’s the assurance that when your product leaves the lab and enters the market, it will meet expectations for reliability, safety, and scalability.

At SVTronics, we help OEMs and ODMs turn promising designs into production-ready solutions through precision testing, industry expertise, and a commitment to quality. Because when your product faces the real world, it deserves to perform flawlessly.

Leave a Reply