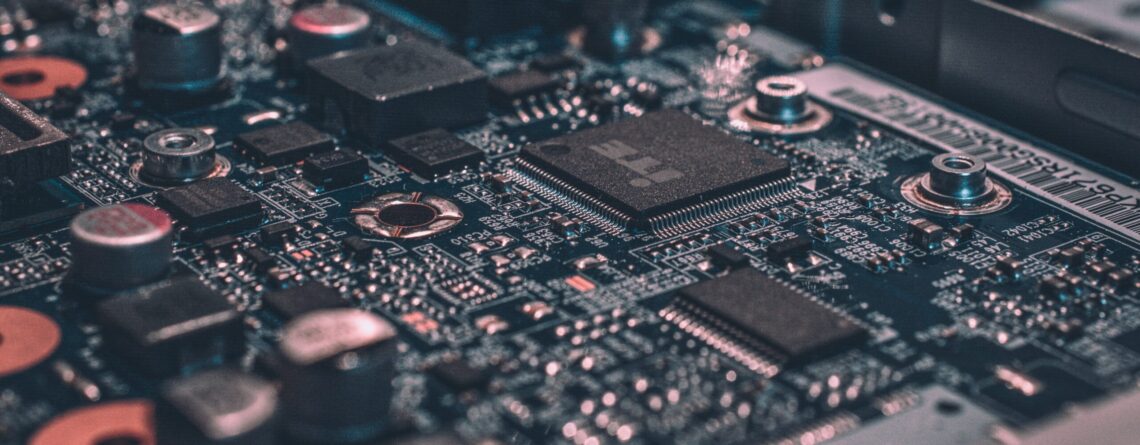

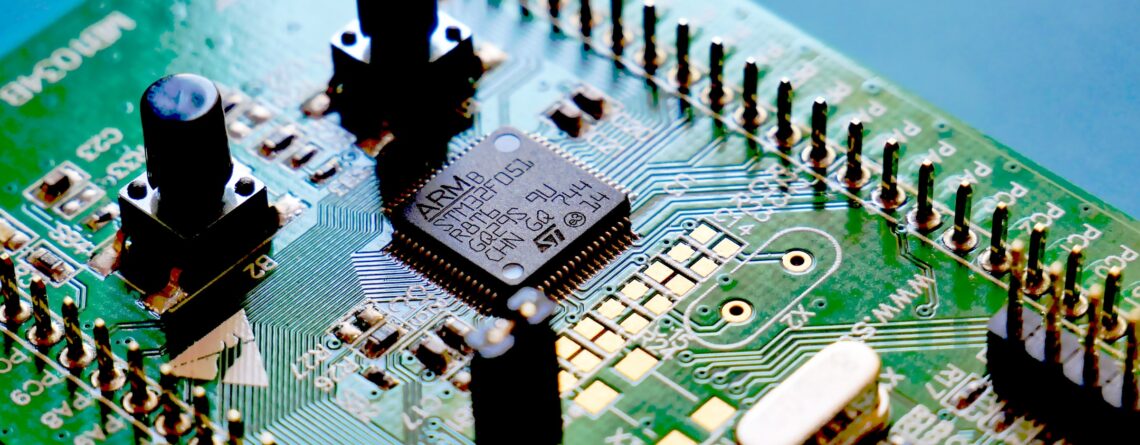

How to Properly Handle, Store, and Ship Your PCB

Proper PCB handling, storage, and shipping methods are critical to ensuring your printed circuit boards arrive in perfect condition. Even the best-designed and-constructed PCBs can be easily damaged when not handled correctly, leading to costly delays and repairs. So, to help ensure your PCBs arrive in perfect working condition, consider utilizing stricter quality control measures...