From Pilot Runs to Mass Production: Why PVT Is the Gateway to Launch Readiness

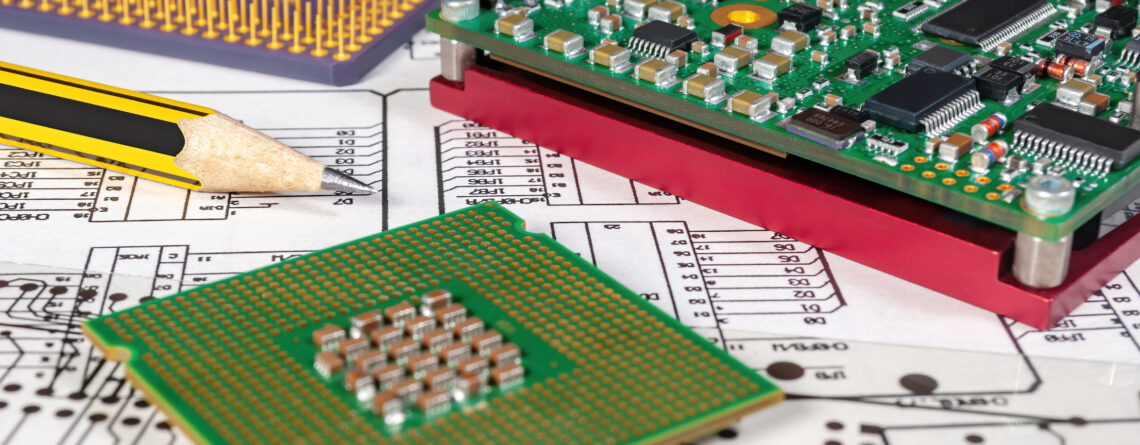

Before any product can move confidently into mass production, it must pass one important milestone: Production Validation Testing (PVT). While EVT and DVT confirm that the design works and is manufacturable, PVT ensures that the entire production ecosystem, from the supply chain to the assembly line to quality assurance, is ready to perform at scale. PVT...