How PVT Ensures Manufacturing Consistency and Quality at Scale

When a product reaches the final stages of development, one challenge remains: ensuring that every unit built at scale meets the same quality, performance, and reliability standards as the initial prototypes. This is where Production Validation Testing (PVT) becomes indispensable.

PVT is the last major verification phase before mass manufacturing, designed to validate not only the product itself but also the production line, assembly workflows, and quality assurance systems. At SVTronics, PVT ensures that manufacturing processes are stable, repeatable, and capable of delivering consistent output at volume.

Why Manufacturing Consistency Matters

In high-volume production, even small variations can have major consequences. Differences in assembly techniques, component tolerances, calibration processes, or testing accuracy can lead to:

- Yield loss

- Increased rework

- Product failures in the field

- Warranty claims

- Brand reputation damage

PVT exists to eliminate these risks by proving that the production line can deliver consistent and reliable results.

How PVT Ensures Quality and Uniformity at Scale

PTW allows for consistent quality at scale by validating assembly line performance, confirming accurate work instructions, verifying quality metrics and test procedures, ensuring predictable yield, and confirming the manufacturing system operates reliably.

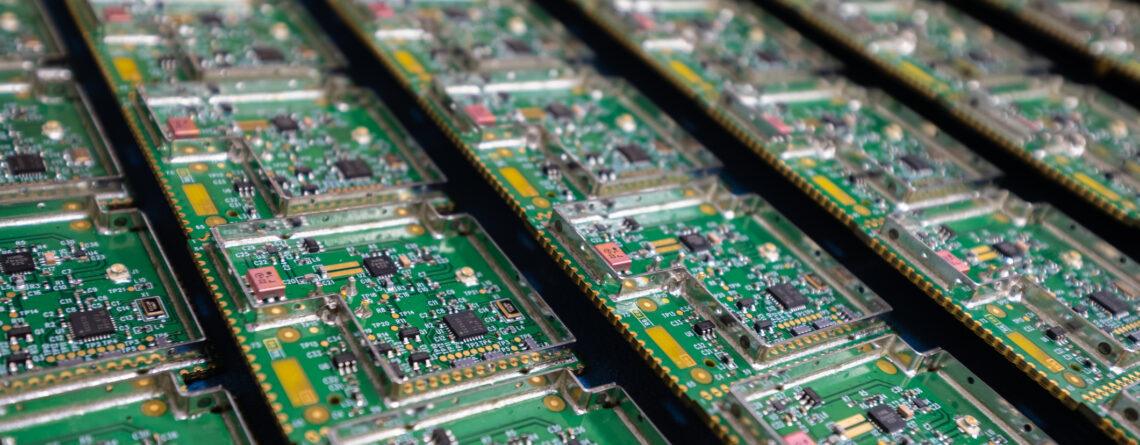

1. Validating Assembly Line Performance

During PVT, builds are executed using the exact equipment, tooling, fixtures, and workflows intended for full production.

This reveals issues that might not surface during EVT or DVT, such as:

- Placement accuracy limitations

- Assembly bottlenecks

- Operator workload imbalances

- Fixture or tooling misalignments

By validating these conditions early, PVT ensures the manufacturing line can run smoothly and predictably.

2. Ensuring Accurate and Complete Work Instructions

Precise and well-documented work instructions are essential for repeatable builds, especially when multiple shifts or operators are involved.

PVT confirms that work instructions are:

- Clear and unambiguous

- Easy to follow

- Optimized for efficiency

- Reflective of real-world assembly challenges

As a result, operators can assemble units consistently with fewer errors.

3. Validating Quality Metrics and Test Procedures

PVT establishes the quality benchmarks that mass production will follow. This includes:

- Calibration and alignment tests

- End-of-line functional testing

- Statistical process control (SPC)

- Automated inspection (AOI, X-ray, ICT, FCT)

If test procedures or acceptance criteria fail to catch issues, or create false failures, PVT identifies and corrects them.

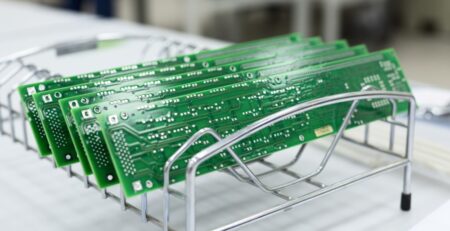

4. Confirming Predictable Yield at Scale

Consistent high yield is one of the most important predictors of manufacturing success. PVT makes yield trends visible by evaluating:

- Assembly defects

- Electrical or mechanical inconsistencies

- Thermal or environmental performance variations

- Process stability across multiple builds

This allows SVTronics to fine-tune processes before full-scale production begins.

5. Locking in a Robust, Repeatable Manufacturing Process

The goal of PVT is to confirm that the entire manufacturing system, not just the product, performs predictably. When PVT is complete, teams have confidence that:

- Every unit meets design intent

- Workflows are optimized

- Quality metrics are stable

- The line can handle projected volume

- Operators and test stations deliver consistent results

This is what enables smooth, uninterrupted mass production.

The SVTronics PVT Process: Designed for Excellence at Scale

At SVTronics, PVT is a highly collaborative and data-driven effort involving engineering, manufacturing, quality, and supply chain teams.

Our PVT approach includes:

- Production-representative builds using final BOMs and tooling

- Validation of assembly line workflows and operator readiness

- Refinement of work instructions, test limits, and acceptance criteria

- Yield tracking and corrective action

- Full quality assurance and reliability testing

- Root-cause analysis for any deviations

By the time a product exits the PVT phase, it is not only ready for mass production but also optimized for long-term manufacturing success.

Manufacturing Consistency Starts with PVT

Production Validation Testing is more than a final checkpoint, it is the process that ensures consistent quality, predictable yield, and reliable manufacturing performance at scale.

For OEM and ODM companies, PVT provides the confidence that every unit rolling off the line will meet design and performance expectations.

At SVTronics, we help teams bring products to market with precision, efficiency, and trust, one validated production line at a time.

Leave a Reply