Military Aerospace and Government – MAG UNIT

With state-of-the-art manufacturing facility SVTRONICS offers advanced manufacturing technology and years of experience to our customers to build their product from start to finish. With a qualified production process, innovative technology, and highly skilled personnel we ensure complete customer satisfaction by delivering best quality products, on time, at the lowest cost.

Our Manufacturing service is strongly supported by highly efficient Program Management which ensures on-time availability. We can operate in various production models, including complete Turnkey, full consignment, and partial consignment. Flexibility is one of our key differentiating characteristics and our customers can always count on us to provide the best service.

With SVTRONICS’ Manufacturing Services you can always be assured that you are getting the best.

Our Quality management system, AS9100, ensures that each product go thru strict quality checks and testing to ensure that we are delivering the best quality products. We work with customers to run customer specific test program to qualify products.

ProtoType Assembly

We support the full product lifecycle from development, prototyping, new product introduction, and more to reduce your product’s time to market.

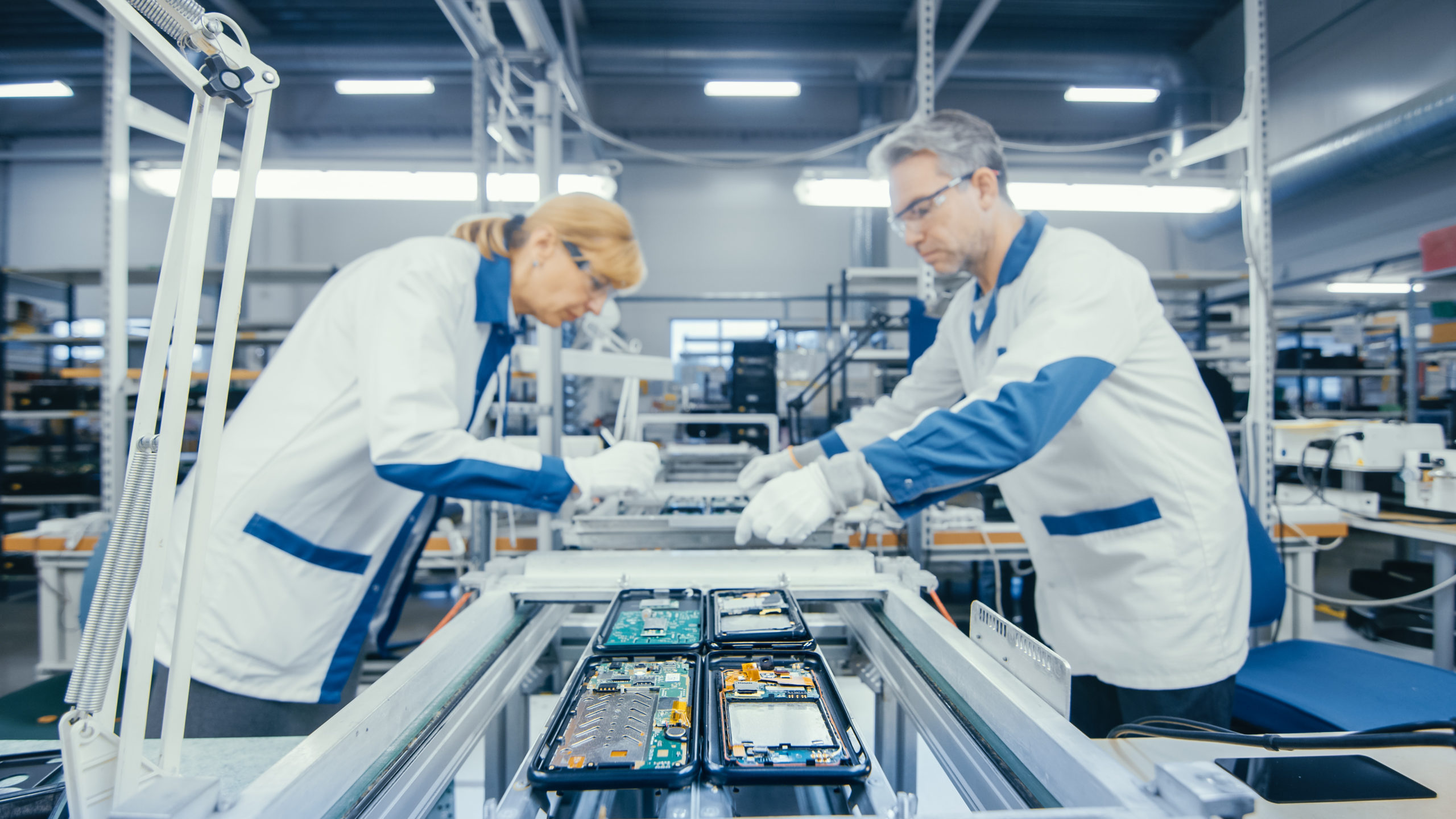

High Volume Production

With a qualified production process, innovative technology, and highly skilled personnel, we ensure complete customer satisfaction by delivering the best quality products, on time, at the lowest cost.

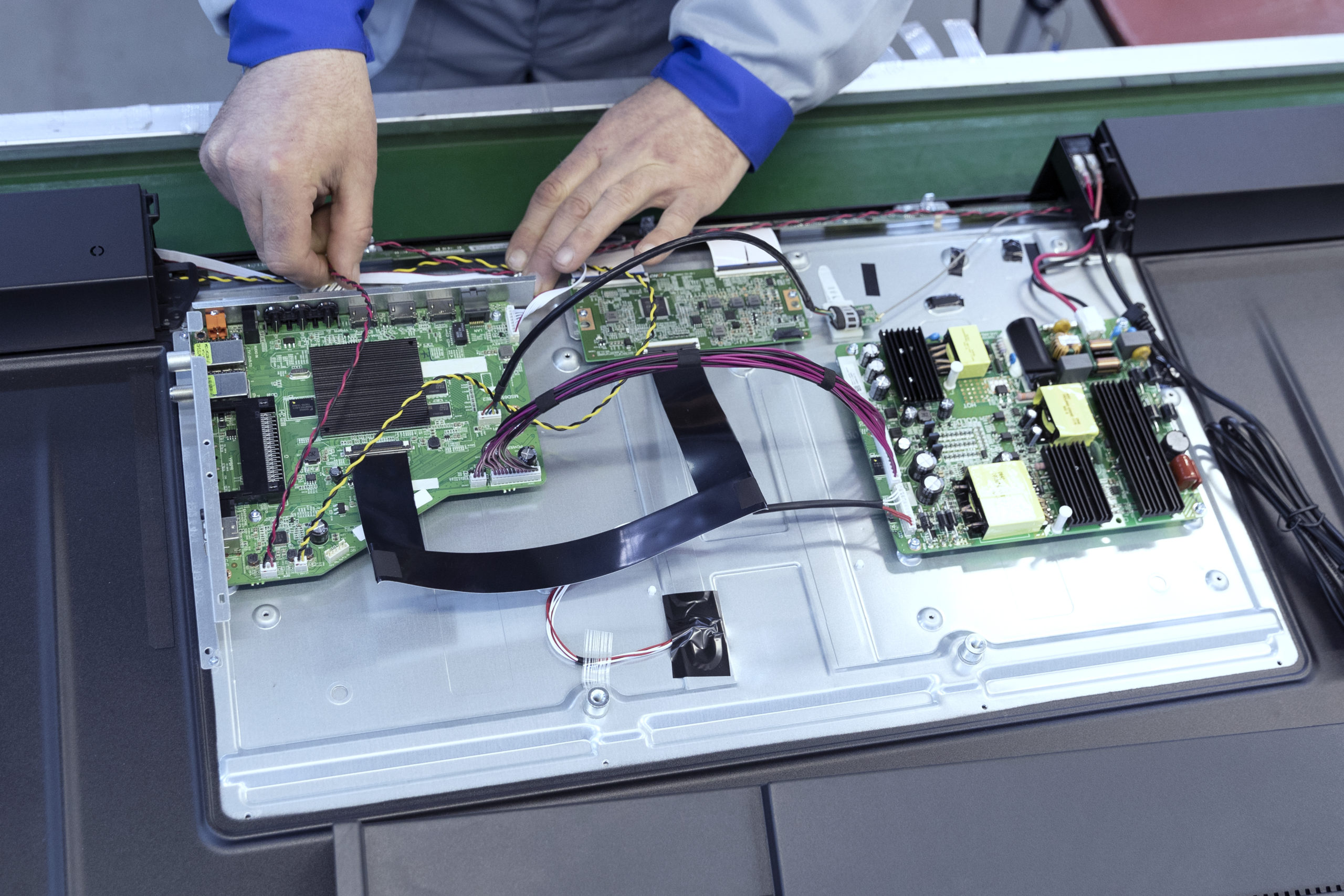

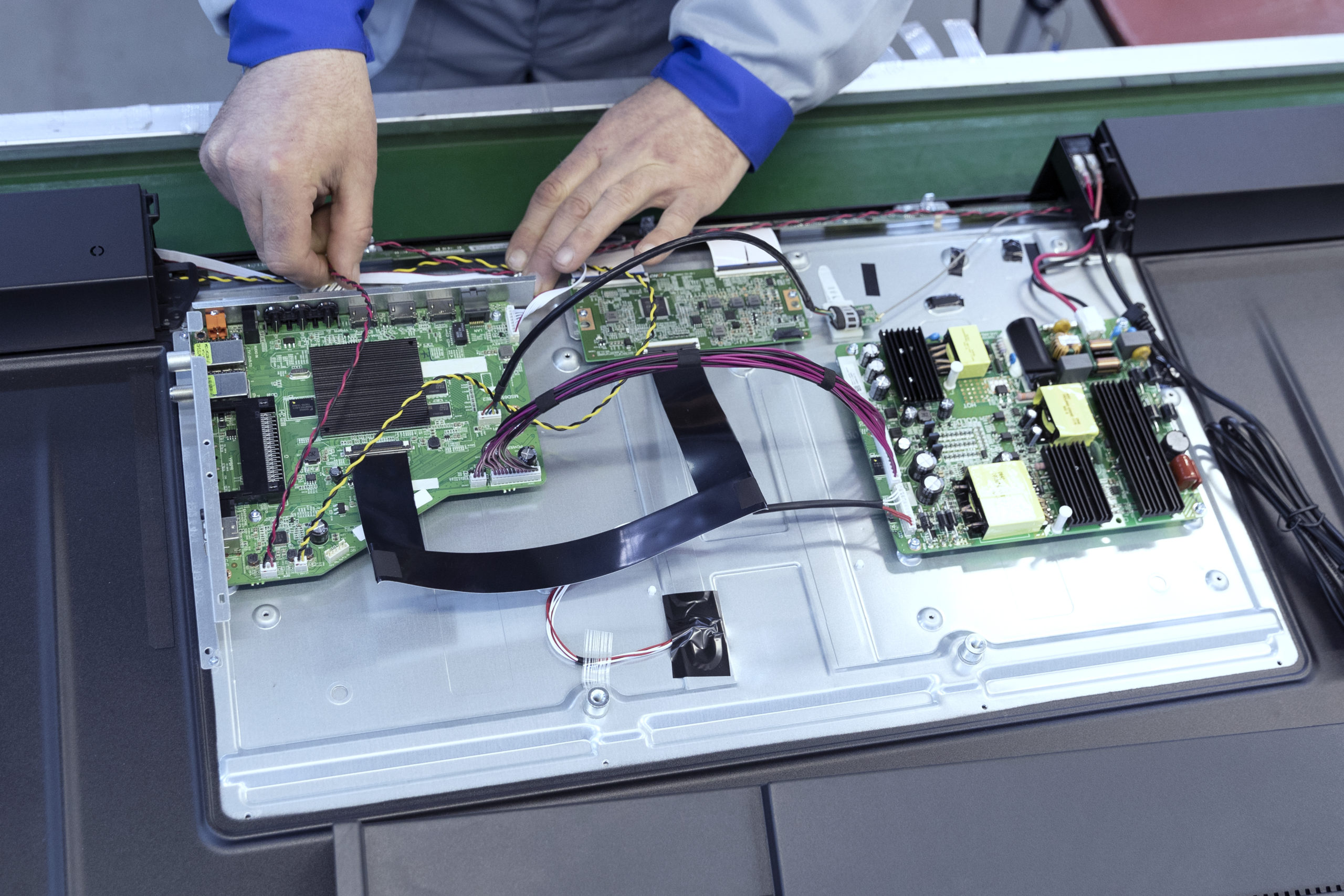

System Integration

SVTronics offers fully integrated solutions to customers who require more than just a PCB assembly. Our MAG team specializes in delivering fully integrated solutions with highly diversified requirements.

Testing

Our highly qualified test engineers have the capability of running various types of electrical tests to ensure the functionality and reliability of boards produced at SVTronics.

Flying Probe Testing

If you have a board that has all nets accessible for flying leads to access, then flying probe testing is a way to ensure continuity of nets on your boards and to ensure the proper impedance measurement on these nets.

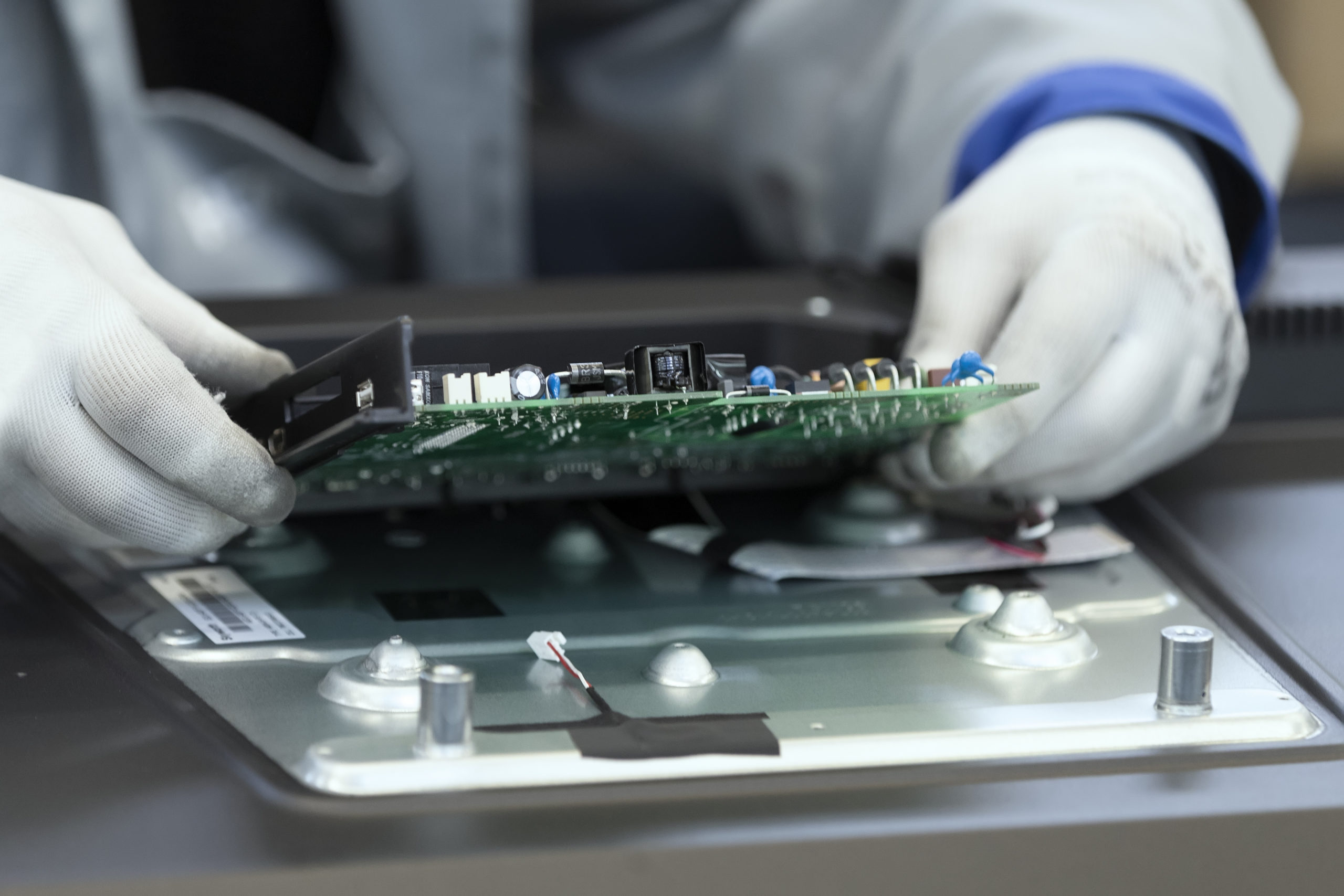

Mechanical Assembly

SVTronics can handle all your mechanical assembly needs for electromechanical products, including press-fit connectors, box build, power distribution and management systems, and custom mechanical products.

Rugged Approaches for Harsh Environments

Solutions combined with leading edge/long life technology, utilizing industrial/automotive spec’d components and with customize packaging to bring long-lived custom COTS solutions.

- New Program

- Upgrade Existing Equipment

- New Solution

- Custom SOW

Whether you need MIL COTS or custom solution, SVTronics MAG Unit can meet your requirements.

MIL Specifications

- MIL-STD-810

- MIL-STD-461

- MIL-STD 167

- MIL-S-901

- Grade A NVIS / Night Vision

- Daylight Readable

- Do160

- PCAP Resistive Touch Monitors Panel PCs

- IP65 Water Resistant

- C1D2 Explosive

- EMI/EMC Compliancy, NSA compliancy

Engineered and Manufactured in the USA

CMMC LEVEL II

U.S. cybersecurity standards applicable to U.S. federal contractors

WHY CHOOSE MIL-COTS EQUIPMENT

- The reliability of commercial-grade long life components and subsystems has improved, eliminating the justification for expensive military specification equipment. Customers can engineer flexible, high-performance systems at lower cost.

- Agencies can benefit from current industrial/automotive approaches and practices; this simplifies the development and deployment of applications, which enables a more rapid adoption of new features and capabilities.

- As the amount of COTS equipment in a system increases, it becomes to easier and cheaper to modify the system, supporting more rapid technology refresh and greater adaptability to change.

- COTS purchases reduce operations and support costs for military customers because suppliers can spread their development costs over multiple market sectors.

MAG UNIT RESOURCES

SVT MAG Group, with over 35 years of expertise in strategic, complex, and highly diversified requirements. Specializing in Engineering – Mechanical, Electrical, and Sustaining, Prototyping, PCB Engineering, Reverse Engineering, and Testing. SVT is AS9100:2015, ISO 13485, ITAR Registered, IPC610, and IPC 620.

SVT meets the DoD’s and other U.S. cybersecurity standards applicable to U.S. federal contractors (Cybersecurity Maturity Model Certification (CMMC Level 2).

Hardware Development

SVT develops custom configurations for customers’ projects using proven COTS strategy and engineering concept methodology to improve reliability, reduce cost, and shorten development time. Every solution begins with embedding already proven and tested COTS engineering and taking the solution to the next level to provide MIL-COTS ruggedization and reliability.

Every solution SVT develops specific mechanical and electrical hardware to address the most demanding configurations and specifications. The development and integration of these solution requires utilizing the best COTS product and attention to detailed MIL Specifications to meet the environmental, functional performances, and support life.

SVT’s Engineering team of mechanical and electrical engineers has over 40 years’ experience and skills required to assist our customers to the requirements they need and advance with development, and end product solution.

SVTronics’ s customers benefit from achieving Mil Spec standards for EMI, Shock, Vibration, Extreme Temperature and Environmental conditions from a MIL COTS solution.

System Integration & Testing

SVTronics offers fully integrated solutions to customers who require more than just a PCB assembly. Our MAG team specializes in delivering fully integrates solutions with highly diversified requirements. Providing more than just build-to-print, Svtronics knows what it takes to turn enclosures, cables, boards, and racks into real solutions. We are constantly engineering innovative, cutting-edge computers that can take on anything – from harsh temperatures and weather extremes to dust, drops, and vehicle vibration.

We specialize in military-rugged smart displays, multi-function displays, computer systems, mass storage, networking, and flat panel displays. Our products and solutions are used in military aircraft, naval ships, submarines, command centers, and airborne surveillance systems. We provide end-to-end solutions for mission-critical applications that meet MIL and DO160E standards. We have demonstrated our unparalleled system engineering and integration experience through programs with major U.S. and foreign prime contractors. Our high-quality, low-risk integrated solutions are engineered to provide immediate, cost-effective responses to their ever-changing environments and missions. We also perform compliance testing and offer FCC Certification, MIL-STD 461, 810, and C1D2

Mechanical Engineering Solutions

SVTronics’ mechanical engineering team works closely with our customers to provide superior industrial engineering concepts and end-product results

- Prototype development and drawings

- Material and manufacturing specifications

- Chassis, enclosure, and panel solutions

- Prototyping of parts – 3D printing

- Manufacturing support

Electrical/Embedded Microcontroller Engineering

SVT Engineering services offers a wide range of embedded microcontroller based solutions. The SVT engineering team can manage a customer’s project from concept to production.

- Electronic Hardware Solutions

- Printed Circuit Board layout

- Embedded/Custom Firmware Development

- First Article/Development

In addition to embedded hardware and firmware engineering services, SVT offers prototyping services that include in-house prototype hardware assembly, firmware creation and testing services.

RUGGED and INDUSTRIAL SYSTEM ENGINEERING

- Customization

- Laptops / Servers / Tablets

- Modified COTS

RACK SYSTEM SOLUTIONS and INTEGRATION

- Custom AL Chassis

- Panel PC’s

- Network Equipment

- Monitors, KVMs and Keyboards

- Touch Screens

- System Testing

- Servers, Video Recording and Mass Storage

SYSTEMS INTEGRATION

System Engineering and Integration to MIL Standards, DO160e, and EU Standards

DISPLAY TECHNOLOGIES

Supports different types of display LCD, OLED, EINK 4K/8K and FOLDING/FLEX technologies –Formats VGA, DVI, HDMI, DP and HG/3G SDI

TESTING

- MIL STD 167 (Vibration)

- MIL STD 461 (EMC/EMI)

- MIL STD 810G (Altitude, Dust, Humidity, Sand, Shock, Thermal, Vibrations, Water ingress, etc.)

- MIL STD 901D (Shock)

- MIL STD 1474E (Noise Limits)

Let’s build something incredible

Upload the details to have our system price your next project