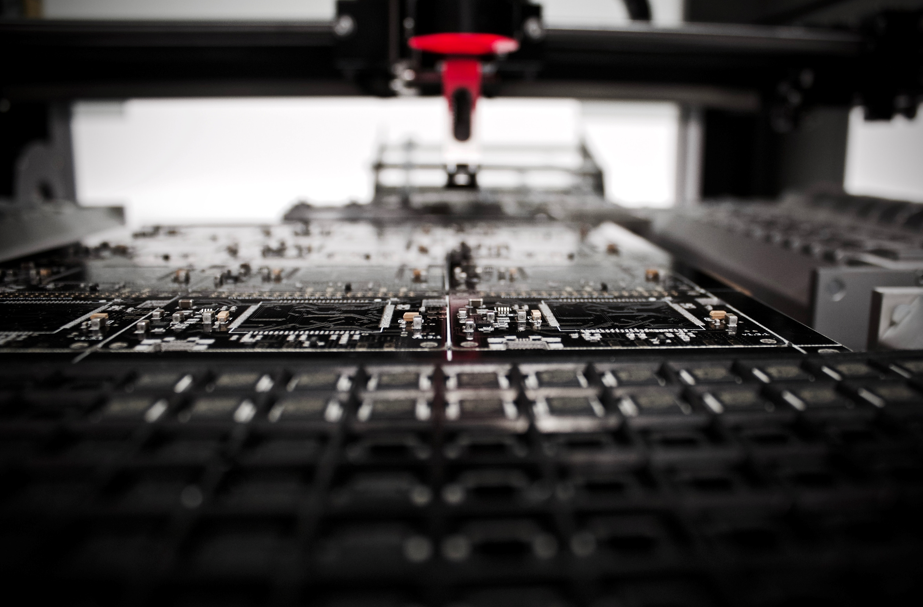

The electronics manufacturing industry is flush with various choices when it comes to PCB. There’s no shortage of material types, from traditional FR-4 boards to newer, high-tech options.

As the need for better and more reliable printed circuit boards (PCBs) continues to grow, so does the importance of knowing how to choose the right PCB material. However, with so many different materials available on the market today, it can be tough to decide which one is right for your needs.

Whether it’s for limiting heat generation, ensuring compatibility with sensitive components, or achieving the best possible signal integrity, the following guide will help you identify the right PCB type for your needs — ensuring a successful outcome for your next PCB project.

Rogers Material

This PCB board material is the namesake of the company that produces it. Rogers material is a dielectric material with very low loss properties, making it a smart choice for high-speed digital and RF applications.

One of the main benefits of Rogers material is its thermal stability. It has a low coefficient of thermal expansion (CTE), meaning it won’t change shape or size much as temperatures fluctuate. Additionally, Rogers material has excellent dimensional stability, meaning it won’t warp or change shape over time.

These benefits make Rogers material ideal for applications where thermal cycling or long-term reliability is essential. And in the case of high-speed digital applications where heat can be an issue, it helps prevent problems like thermal expansion and contraction from affecting the integrity of the circuit.

Choosing Rogers material is a prime choice for those needing electronics manufacturing in the realms of:

- High-speed digital

- RF and microwave

- Military and aerospace

With its many benefits, Rogers material is the best choice when you need to adhere to tight dimensional tolerances and when thermal stability is critical. Available in both rigid and flex options, Rogers material also provides excellent flexibility in the design process.

Metal PCB Boards

When it comes to manufacturing lights of any kind — from traffic lights to LED light bulbs — metal PCBs are the way to go. Metal boards are highly durable and resistant to fire and heat, making them ideal for applications where safety is a priority.

One of the most important benefits of metal PCBs is their superb thermal conductivity. So if heat is an issue in your circuit design, a metal PCB can help dissipate it more effectively than other PCB types.

Made primarily from aluminum, metal PCBs are much lighter than other options like FR-4, which means they are a wise choice for applications where weight is a concern, such as in the aerospace industry.

If you’re looking for a PCB board material that offers superb thermal conductivity and improved durability, metal PCBs are your go-to. Some of the most common applications for metal PCBs include:

- Automotive

- Industrial

- Power supplies

- Lights and lighting fixtures

Metal PCBs are your best option to protect your circuit from fire, heat, or water damage. Also, consider using metal PCB boards made using copper and other alloy mixes for customized thermal conductivity results.

FR-4 PCB

When you need a general-purpose PCB, FR-4 is often the best choice. It’s one of the most popular materials used in electronics manufacturing and is typically made from a glass-reinforced epoxy laminate that incorporates fiberglass as a feature in its design.

FR-4 PCB is known for being very strong and rigid, so it’s best used in applications where the circuit will be subject to stress or vibration. It’s also resistant to many common chemicals, including acids, alkalis, and oils making it an excellent option for industrial applications.

FR-4 offers stability and reliability at a reasonable price, making it a great choice for most PCB projects. It’s also compatible with a wide range of electronic components, making it a versatile PCB material.

Furthermore, FR-4 offers a good balance of properties, including high mechanical strength, good dimensional stability, and excellent electrical insulation. Some of the most common applications for FR-4 PCBs include:

- Power supplies

- Computers and computer peripherals

- Consumer electronics

- Telecommunications equipment

If you’re looking for a versatile and affordable PCB material, FR-4 is likely your best bet. It’s compatible with a wide range of electronic components and offers many benefits for those seeking a general-purpose PCB.

High-Density Interconnector

Rapidly becoming one of the most popular PCB options, HDI (High-Density Interconnector) offers many benefits over traditional PCBs.

One of the main advantages of HDI is that it provides a higher density of interconnections than other types of PCBs. This means that more circuitry can be crammed into a smaller space, making it ideal for miniaturized electronic devices.

HDI also offers improved heat dissipation and better signal integrity than other PCB choices. This is because HDI features finer traces and smaller vias than traditional PCBs.

Some of the most common applications for HDI include:

- Cell phones

- Tablets

- Laptops

- Wearables

HDI is the perfect PCB material for applications where space is limited and improved signal integrity is required. If you’re looking to manufacture miniature electronic devices, HDI is a standout. Additionally, thanks to its design, HDI is sufficiently durable for BPA and QFP packaging.

Pick the Best Material for Your Project

By taking the time to understand your options, you can choose the best material for the job and ensure the success of your next PCB project.

If you’re looking for a versatile PCB material compatible with a wide range of electronic components, FR-4 is a good choice. On the other hand, if you need a PCB that offers superb thermal conductivity, metal is the way to go. Those that want to prioritize protecting the integrity of circuitry should choose Rogers material. And if it’s PCB for miniature electronics, HDI should be your PCB of choice.

Once you’ve selected the perfect PCB, partner with a reliable and experienced PCB manufacturer who can help you bring your project to life. Here’s how to find an EMS partner so you can get started on your next PCB project.