State of the Art Factory with Advanced Capabilities

With a state-of-the-art manufacturing facility, SVTronics offers advanced manufacturing technology and years of experience to our customers to build their products from start to finish. With a qualified production process and highly skilled personnel, we ensure complete customer satisfaction by delivering the best quality products on time at the lowest cost.

ProtoType Assembly

We support the full product lifecycle from development, prototyping, new product introduction, and more to reduce your product’s time to market.

High Volume Production

With a qualified production process, innovative technology, and highly skilled personnel, we ensure complete customer satisfaction by delivering the best quality products, on time, at the lowest cost.

System Integration

SVTronics offers fully integrated solutions to customers who require more than just a PCB assembly. Our MAG team specializes in delivering fully integrated solutions with highly diversified requirements.

Testing

Our highly qualified test engineers have the capability of running various types of electrical tests to ensure the functionality and reliability of boards produced at SVTronics.

Flying Probe Testing

If you have a board that has all nets accessible for flying leads to access, then flying probe testing is a way to ensure continuity of nets on your boards and to ensure the proper impedance measurement on these nets.

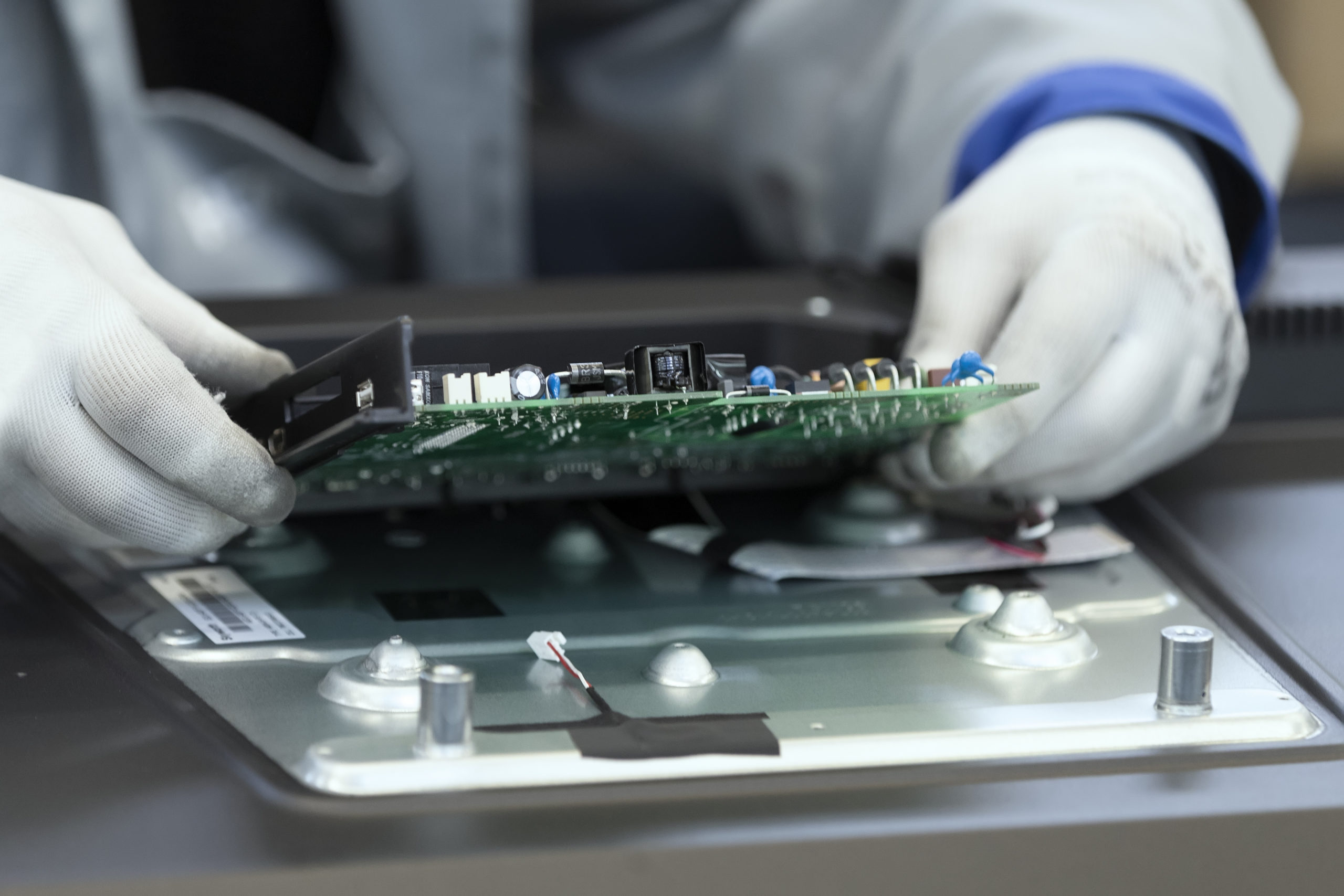

Mechanical Assembly

SVTronics can handle all your mechanical assembly needs for electromechanical products, including press-fit connectors, box build, power distribution and management systems, and custom mechanical products.

PCBA Testing

Our highly qualified test engineers have the capability of running various types of electrical tests to ensure the functionality and reliability of boards produced at Svtronics. We can perform functional tests tailored for each product or perform flying probe tests. Functional testing ensures that the boards are manufactured fully functional before they get shipped out. Our functional test stations have various test and measurement instruments, from multimeters to oscilloscopes and signal generators. We can capture and analyze all types of signals and waveforms as per the customer requirement.

Flying Probe Testing

If you have a board that has all nets accessible for flying leads to access, then Flying probe testing is a way to ensure continuity of nets on your boards and to ensure the proper impedance measurement on these nets. Our Seica Flying Probe testers used to achieve just that. Flying probes can be programmed to measure the electrical characteristics of each net as per the design. They access component pins directly through automated probing. We can implement any testing strategies as per the customer requirement.

In-Circuit Testing

SVTronics also has in-circuit test capabilities, and we can perform all the tests done by a flying probe and more using the In-Circuit tester. In-circuit tests utilize specialized bed of nail fixtures to access electrical contact points to measure continuity and various other electrical properties. It can also perform In-Circuit programming and also test the functionality of circuits.

Mechanical Assembly

We can handle all your mechanical assembly needs for electromechanical products, including press fit connectors, box build, power distribution & management systems, and custom mechanical products with potting, coating, and other specialized assemblies.

Quick Turn ProtoType Assembly

SVTronics supports the full product lifecycle from development, prototyping, new product introduction, and more to reduce your product’s time to market. We understand the need to get your prototypes built quickly and accurately, and our manufacturing lines are set up to do just that. We offer quick turn prototype assembly to ensure that you do not lose time waiting on the boards to be built. Your goals become our own, and we adopt a flexible approach to help you achieve them.

We help our clients design products that are manufacturable and guide them through selecting parts, vendors, and more to ensure that products can be built in high volume when the customer is ready to launch the product. We also help customers optimize the design and prepare any special fixtures or tooling required to increase the production throughput during high volume production. We understand you may not get the design right the first time. Our dedicated manufacturing personnel can assist you in reworking boards and applying temporary fixes even after the boards are built.

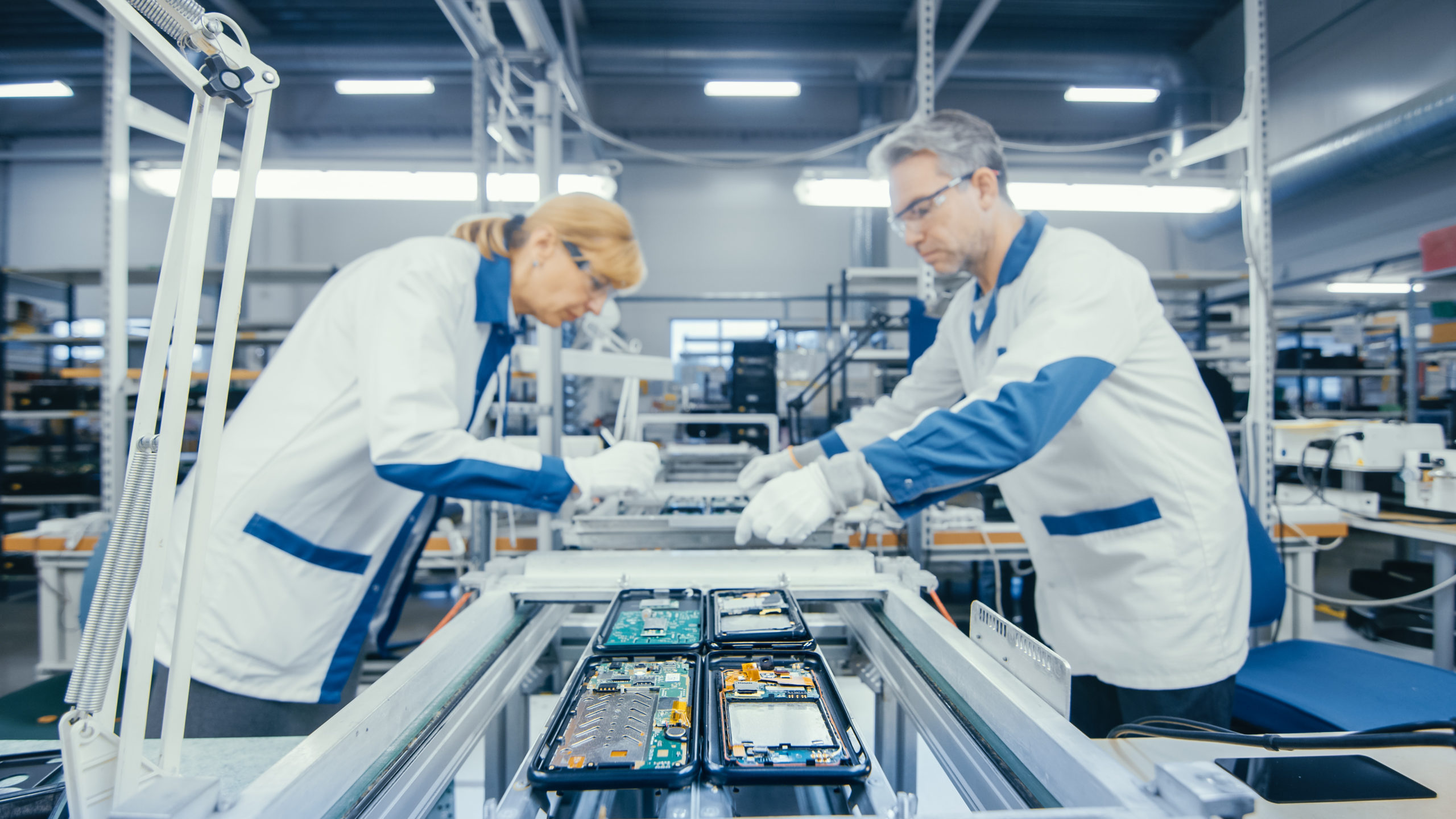

High Volume Production

SVTronics manufacturing facility is equipped to meet your high-volume production needs. Our expert production team can meet any manufacturing challenges and build products to meet customer requirements. With a qualified production process, innovative technology, and highly skilled personnel, we ensure complete customer satisfaction by delivering the best quality products, on time, at the lowest cost.

SMT Assembly

Our state-of-the-art equipment can build highly complex boards with speed, precision, and flexibility in mind with six different SMT lines. These lines have automated screen printers with vision capabilities, nitrogen purged reflow oven, and inline Automated Optical Inspection to assure the quality of the boards assembled on our production line. Our SMT line has:

- Placement capability for 01005 package components

- Package on package

- CSP, QFP

Thru Hole Assembly

Our wave solder machines, selective solder station, and IPC can support all your thru hole assembly needs. Our machines can handle both lead-free and leaded assembly. All our manual assembly staff in IPC-J is standard trained and certified.

Our electronic manufacturing services are strongly supported by a highly efficient material procurement team that ensures on-time availability of components by keeping a watch on the cost. We can operate in various production models, including complete turnkey, full consignment, and partial consignment. Flexibility is one of our key differentiators, and our customers can always count on us to provide the best service.

Our quality management system ensures that each product goes through strict quality checks and testing to ensure that we deliver the best quality products. We work with customers to run customer-specific test programs to qualify products.

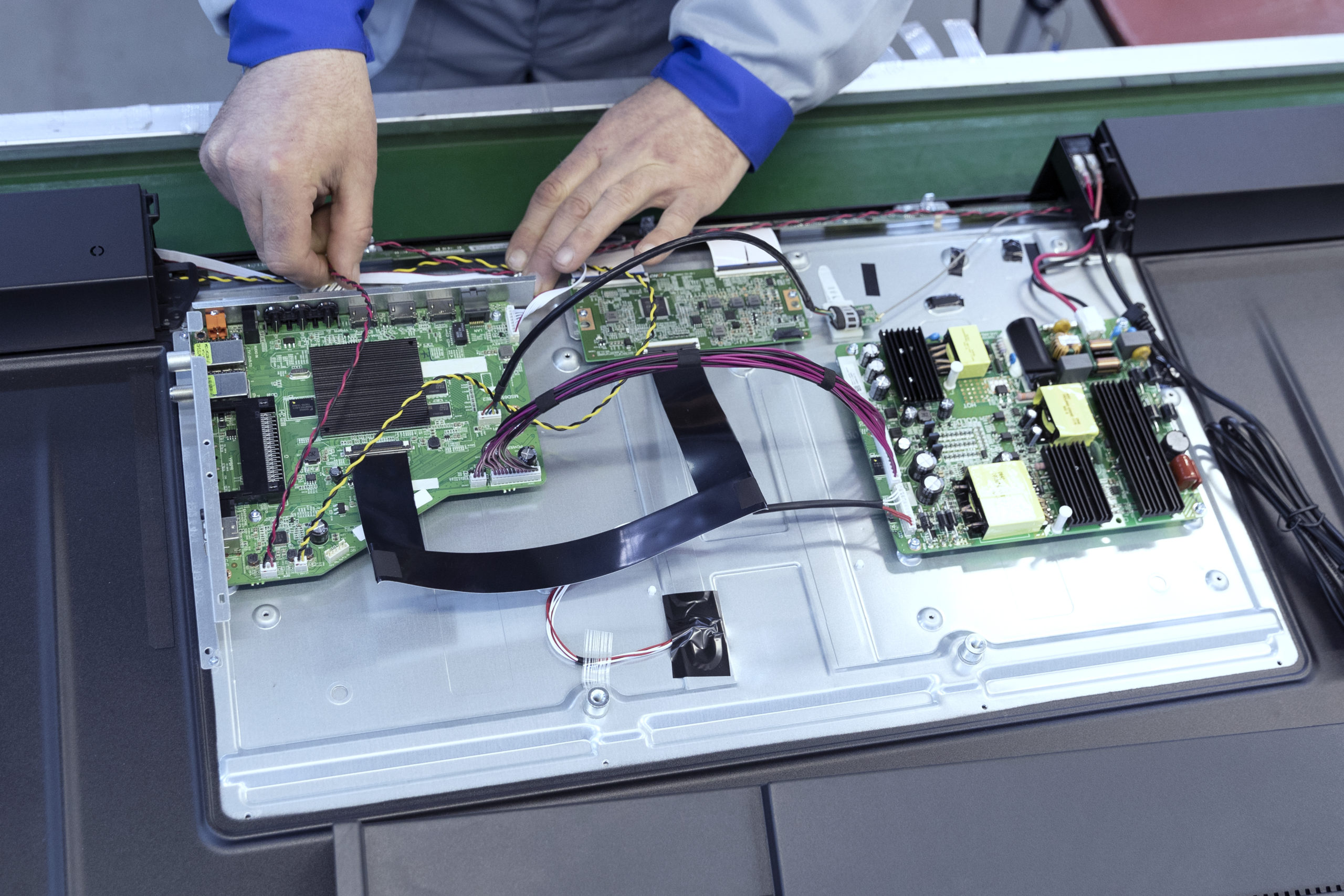

System Integration & Testing

SVTronics offers fully integrated solutions to customers who require more than just a PCB assembly. Our MAG team specializes in delivering fully integrates solutions with highly diversified requirements. Providing more than just build-to-print, Svtronics knows what it takes to turn enclosures, cables, boards, and racks into real solutions. We are constantly designing innovative, cutting-edge computers that can take on anything – from harsh temperatures and weather extremes to dust, drops, and vehicle vibration.

We specialize in military-rugged smart displays, multi-function displays, computer systems, mass storage, networking, and flat panel displays. Our products and solutions are used in military aircraft, naval ships, submarines, command centers, and airborne surveillance systems. We provide end-to-end solutions for mission-critical applications that meet MIL and DO160E standards. We have demonstrated our unparalleled system design and integration experience through programs with major US and Foreign Prime contractors. Our high-quality, low-risk integrated solutions are designed to provide immediate, cost-effective responses to their ever-changing environments and missions. We also perform compliance testing and offer FCC Certification, UL, ETL, and CE Marking.

Final Assembly & Out of the Box Experience

When it is time to put it all together and get the units to customers’ hands, we help assemble your final product with all required labeling and marking, box them individually, and include all the required accessories, user guides, etc. We also work with our customers to design out-of-the-box experiences for their customers.

Let’s build something incredible

Upload the details to have our system price your next project